The required energy for the pharmaceutical removal in the cavitation reactor

Description

This project focuses on the energy requirements for wastewater treatment regarding pharmaceutical removal with hydrodynamic cavitation. It is aimed to compare this energy with energy requests for e.g., ozonation or UV/H2O2. The main objective of the project is to identify the mechanism responsible for the pharmaceutical compound decomposition due to the collapse of cavitation bubbles. In this context, the main consideration will be devoted to the energy released from the collapse of cavitation bubbles as interdisciplinary research between energy harvesting from the bubble dynamics and water remedy.

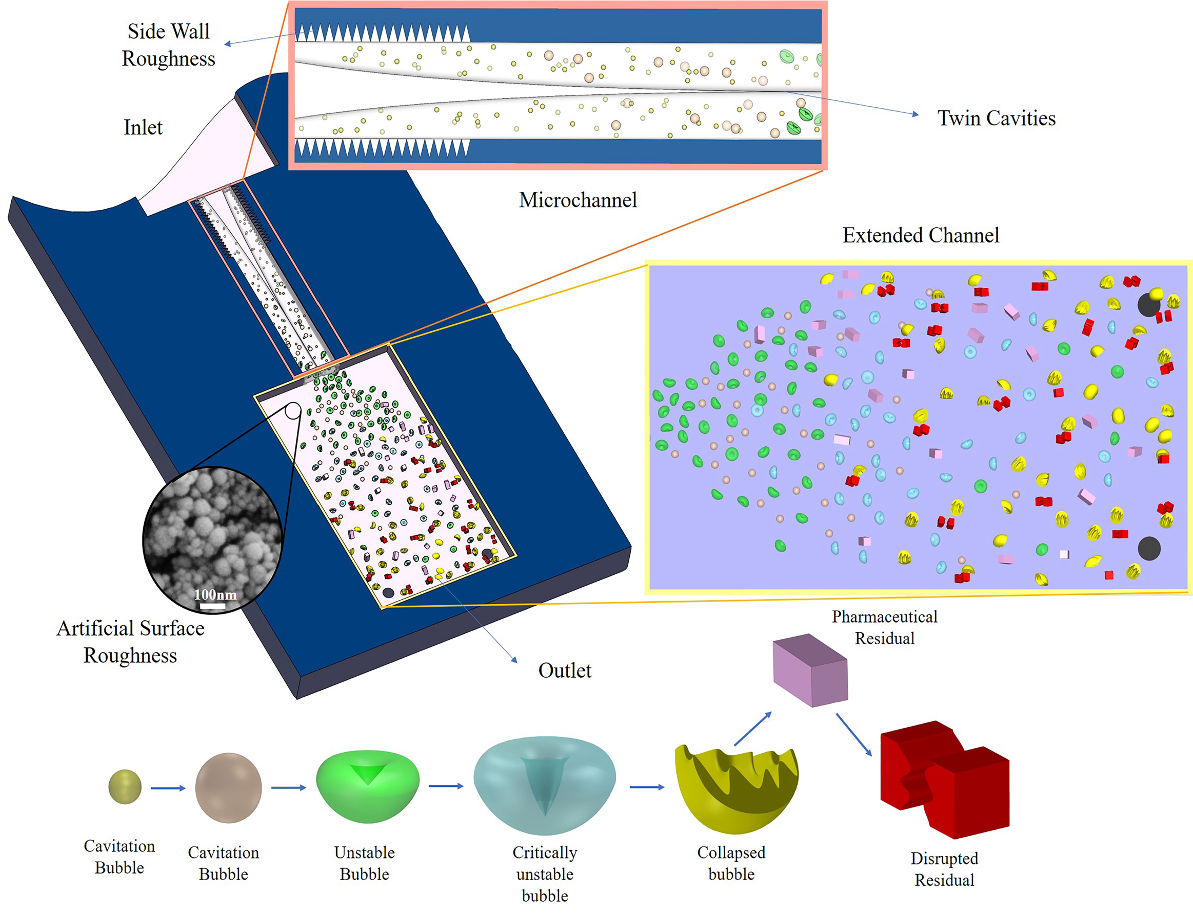

In this regard, we aim to establish an experimental setup in which a microfluidic device capable of generating hydrodynamic cavitation is installed. The microfluidic device consists of multiple microchannels working in parallel, while the lateral walls are equipped with engineered roughness elements. Standard microfabrication methods are used to establish the primary reactor. At the first stage of experiments, the reactor's efficiency is evaluated using a sonochemical approach such as the Weissler reaction to assess the hydroxyl radical release rate. Furthermore, for the first time in the literature, the energy level of the emerging cavitating flows with different intensities is indirectly evaluated by analyzing the radical release rate. Hence, the correlation between the input energy, physical properties of the reactor, and release chemical energy is presented.

Therefore, this preliminary study will help us to understand the physical and chemical aspects of the energy released from the collapse of the cavitation bubbles and pave the way to design and manufacture an efficient hydrodynamic cavitation reactor to treat and recycle municipal and especially medical wastewater for our future projects.