FriText Friction Control Through Surface Texturing

The friction and wear have a great impact on energy consumption, economic expenditure, and CO2 emissions. Almost 23% of the world’s total energy consumption originates from tribological contacts (20% from friction and 3% from wear). Implementing advanced tribological technologies can have a great influence on better control of frictional losses, and wear protection and can significantly reduce worldwide CO2 emissions. Those problems have a special impact on the automotive industry and manufacturing.

Purpose and objective

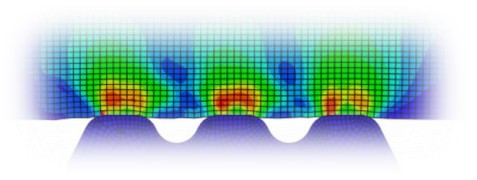

The main objective of the project is to determine the surface texturing method to control the coefficient of friction and surface protection against wear, to improve the tribological properties of machinery components e.g., in engines or power generation equipment.

The project includes two main goals:

- Develop a modification of existing abrasive processes to make the desired the texture on the surface

- Develop a method for the surface evaluation after texturing by using existing and new functional parameters

Current state

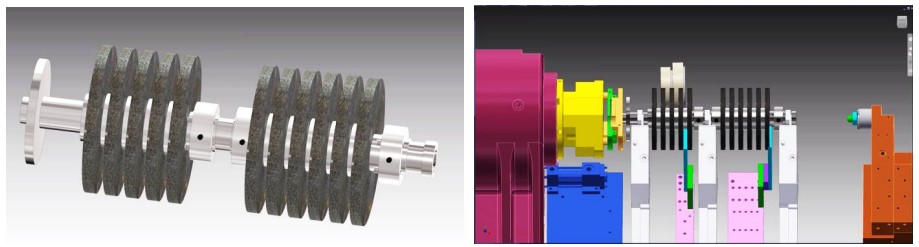

The project is in the preparation phase for industrial tests. The texturing via grinding will be performed at Powertrain Engineering Sweden AB. Special fixtures are under preparation for big and small components. The Husqvarna’s crankpin journals will be textured and assembled into the engines for different type of testing (normal operation test, laboratory engine tests, and other).

Consortium

Project contact persons

Coordinator

Manager

Contributor

Contributor