Exchangeable Spindle Unit Reliability Investigation

Condition Monitoring is a key technology for the extension of the maintenance period and the overall lifecycle of machine tool components. The in-situ determination of potential faults leverages the potentials to predict future errors and failures. The severity of the failure is quantified through its impact on the operation of the asset. A deeper understanding of the component-level reliability in the machine tool is essential for the determination of the degradation.

Purpose and objective

The reliability assessment of the system depends on a number of factors:

- Position of the sensor

- Interface of the sensor with the physical item

- Data analytical tools

- Methods and models of the transition of functional failure between component and system

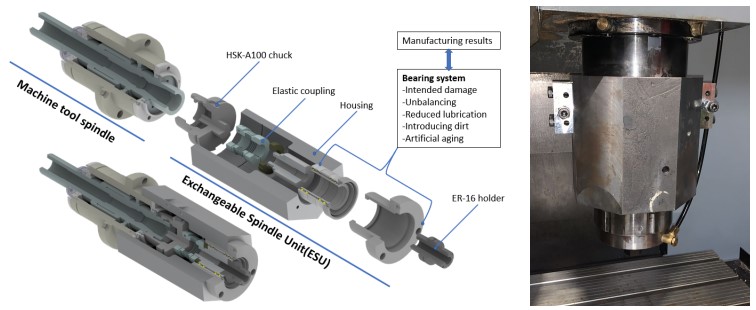

The exchangeable spindle unit (ESU) allows for the capturing and mapping of the failure transition of bearings during manufacturing operations. This generates a database for the determination of the reliability and severity of different bearing systems in the context of milling spindles. The results allow for the evaluation of new sensor interfaces, information processing, and status prediction methods.

Possible impacts

In-situ failure prediction is a complicated process. To increase the knowledge about the system status, the ESU aims at highest accessibility. The support of machining operations gives access to highly relevant operational data which can set the foundation for a condition monitoring benchmark for new analysis methods. Additionally, the performance can be optimized and controlled to deepen the understanding of spindle metrology in general.

Project contact persons

Coordinator

Contributor