Next generation methods, concepts and solutions for the design of robust and sustainable running gear (NEXTGEAR) (RV37)

Project Coordinator - UNIFE

Project Leader at KTH - Sebastian Stichel

Scientists at KTH - Carlos Casanueva Perez, Rickard Persson, Per Wennhage, Saeed Hossein Nia, Anton Shipsha, Rocco Giossi

Other Scientists - From 16 European Partners

Source of Funding - European Commission (Horizon 2020)

The rail sector has recently seen only limited changes in the running gear. A reason is that innovations have the tendency to increase the first cost of the running gear while they reduce the LCC by reduced maintenance costs. The long-term cost reduction, however, is not easy to quantify.

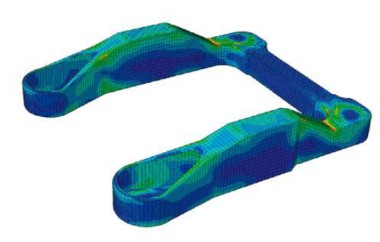

This dilemma will be addressed in WP1 where an updated so-called Universal Cost Model based on the one from the ROLL2RAIL project will be developed that makes it possible to judge the economic impact of the innovation suggested for an operator using the vehicle. How can the costs for buying, operating and maintaining the vehicle be influenced? Lower bogie weight would reduce wheel-rail forces and allow for higher payload. In WP2, the project is going to suggest ideas that are based both on the use of new materials and new manufacturing methods. Simulation techniques will be explored to allow optimisation of designs. It will be investigated whether required properties of the running gear such as stiffness and damping could be distributed through the structure rather than requiring specific components. In parallel, active control strategies will be investigated to improve the level of ride comfort or reduce wheel and rail damage.

The wheelset is another extremely important and safety-critical component in a rail vehicle. Since it represents a so-called “unsuspended mass” there is a desire to minimize the wheelset weight. The main objective of WP3 is a feasibility study on the use of composite materials for the construction of railway wheelsets. Technology concepts for a lightweight wheelset will be defined. The main focus-areas are material selection, durability, manufacturing process and joining methods.

The output of this project will be an important input for the parallel member project in IP1 (PIVOT-2) both regarding the Cost Model and the technical innovations. There will also be a contribution to the overall Shift2Rail KPI’s and partly IP3.