- Introduction to simulation methods, limitations and possibilities in general.

- Review of some of the modeling software today.

- Exercises introducing the students to some modeling software, including limitations and possibilities of the specific software.

- Selection and planning of a modeling problem.

- Solution of the modeling problem project.

- Written and oral presentation of the project.

MH2042 Simulation and Modeling Toolbox 6.0 credits

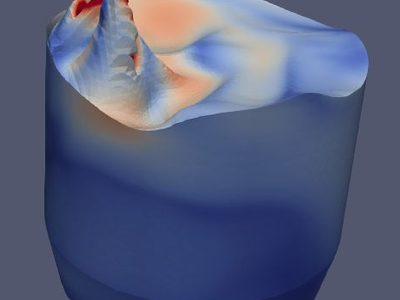

Today a wide variety of simulation tools are available to help with engineering tasks. Numerical solutions of the incredibly complex Navier-Stokes equations have been around for almost a century; in the early 20th century it was performed by human computers and today it can be performed on any desktop computer or on various super computers around the world. In materials processing simulation of steel flows is a very useful tool to aid with process understanding – many of the processes have such an environment that regular experimental methods cannot be used and as such modeling can complement experimental techniques. It is also important to note that problem solving skills and innovation are highly valued in any industry and as such there will be a focus on solving actual industrial problems in this course.

Information per course offering

Information for Autumn 2025 Start 25 Aug 2025 programme students

- Course location

KTH Campus

- Duration

- 25 Aug 2025 - 24 Oct 2025

- Periods

Autumn 2025: P1 (6 hp)

- Pace of study

50%

- Application code

50024

- Form of study

Normal Daytime

- Language of instruction

English

- Course memo

- Course memo is not published

- Number of places

Min: 10

- Target group

- Open for application for TTMVM2. Elective for all programs as long as it can be included in your programme.

- Planned modular schedule

- [object Object]

- Schedule

- Part of programme

- No information inserted

Contact

Course syllabus as PDF

Please note: all information from the Course syllabus is available on this page in an accessible format.

Course syllabus MH2042 (Autumn 2019–)Content and learning outcomes

Course contents

Intended learning outcomes

After the course you should be able to.

- Define and setup a materials process problem using common commercial software.

- Apply the equations of change on materials process problems.

- Interpret the simulation results.

- Have some basic knowledge of the limitations of the software.

- Plan a project and present the results in a scientific manner, both orally and written.

Literature and preparations

Specific prerequisites

In total 165 higher education credits in the main field of study of Technology.

Recommended prerequisites

- Fluid mechanics and heat transport (MH1037 Transport Phenomena or similar)

- Numerical methods (SF1551 Numerical Methods, Basic Course or similar)

Literature

Examination and completion

Grading scale

Examination

- SEM1 - Seminar, 2.0 credits, grading scale: A, B, C, D, E, FX, F

- PRO1 - Project Assignment, 4.0 credits, grading scale: A, B, C, D, E, FX, F

Based on recommendation from KTH’s coordinator for disabilities, the examiner will decide how to adapt an examination for students with documented disability.

The examiner may apply another examination format when re-examining individual students.

If the course is discontinued, students may request to be examined during the following two academic years.

Dragon’s Den - Problem Formulation Seminar

During the problem formulation presentation (max 5 minutes!) a few external "venture capitalists" will judge your projects based on your presentations

Important Points:

- Background (including state-of-the-art)

- Goal with project and also time to accomplish the goals.

- Deliverables (some means to show you have achieved the goals).

Examiner

Ethical approach

- All members of a group are responsible for the group's work.

- In any assessment, every student shall honestly disclose any help received and sources used.

- In an oral assessment, every student shall be able to present and answer questions about the entire assignment and solution.