- Basics of automation technology

- Description of sequence of events

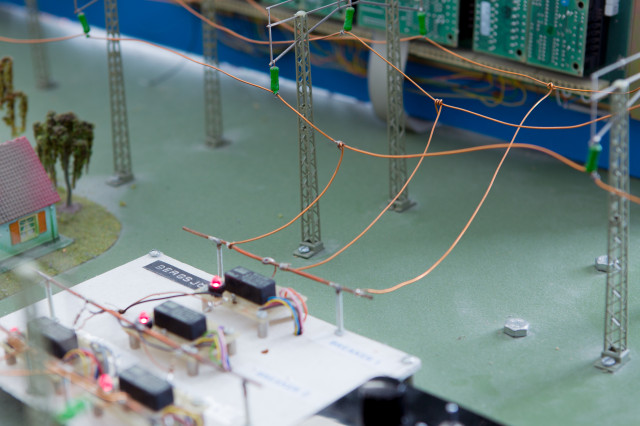

- PLC technology

- Use of sensors and actuators in the manufacturing industry

- Introduction to assembly techniques - feeders, joining, DFA

- Use of robots

- Material handling

- Environmental, human, and economic conditions for the design and use of automated systems

- Automation challenges from a maintenance perspective.

After passing the course, the student should be able to:

1. Use correct terminology, define concepts, describe the functions and properties of components within automation.

2. Explain general principles, methods, and equipment for control and automation - how they work, how they are used and programmed, including industrial robots.

3. Systematically describe the sequence of events in a manufacturing equipment, develop logical solutions and control charts, and develop appropriate PLC programs in codeSys.

4. Choose suitable components for the current application, such as actuators, sensors, control systems, and industrial communication equipment.

5. Design, program, and commission simpler automated systems where processing, material handling, assembly, coordination, and monitoring are included in the control tasks.

6. Explain the transformation in the industry towards digitalization and higher levels of automation.

7. Identify problems in automated systems from a maintenance perspective and suggest solutions.

8. Reason about safety and environmental aspects related to automation and argue for or against different positions in a nuanced way.

9. Describe the environmental, human, and economic conditions for the design and use of automated systems.