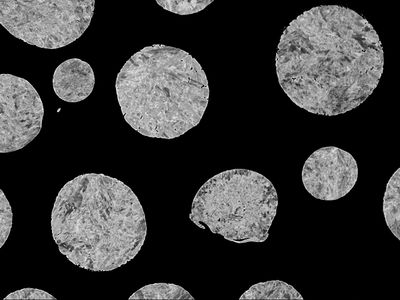

Fabrication of metallic powders and methods for their characterisation. Compaction and sintering of ironbased powder and cemented carbide powder. Compaction by uni-axial and isostatic pressing and the use of pressing aids. Thorough analysis of chemical equilibria and diffusion processes during sintering of sinter steel and cemented carbides. Sintering theory and the influence of different processing conditions, wetting and surface diffusion. Solid phase as well as liquid phase sintering are exemplified by applications on sinter steel and cemented carbides. Advantages and limitations of powder metallurgy materials are discussed from technical and economical point of views.

MH2100 Powder Metallurgy 6.0 credits

This course provides the students with knowledge about the field of powder metallurgy and teaches them generic principles associated with creating powders and fabricating engineering shapes from those powders.

Topics covered are powder production and characterization, compaction and shaping of powder, full-density process such as additive manufacturing and hot isostatic pressing, liquid and solid state sintering. Special focus is on additive manufacturing, cemented carbides and steels.

Information per course offering

Information for Autumn 2025 Start 27 Oct 2025 programme students

- Course location

KTH Campus

- Duration

- 27 Oct 2025 - 12 Jan 2026

- Periods

Autumn 2025: P2 (6 hp)

- Pace of study

33%

- Application code

50027

- Form of study

Normal Daytime

- Language of instruction

English

- Course memo

- Course memo is not published

- Number of places

Min: 10

- Target group

- Open for application for TTMVM2. Elective for all programs as long as it can be included in your programme.

- Planned modular schedule

- [object Object]

- Schedule

- Part of programme

- No information inserted

Contact

Course syllabus as PDF

Please note: all information from the Course syllabus is available on this page in an accessible format.

Course syllabus MH2100 (Autumn 2019–)Content and learning outcomes

Course contents

Intended learning outcomes

After the course the student should be abel to:

- about powder metallurgical materials and their fabrication processes.

- of materials of special importance for the Swedish PM-industry.

Literature and preparations

Specific prerequisites

The course or a similar one like:

MH2027 Micro and Nano Structures.

Literature

Anges i kurs-PM, vid kursstart.

Examination and completion

Grading scale

Examination

- TEN2 - Written examination, 4.0 credits, grading scale: A, B, C, D, E, FX, F

- LAB2 - Laboratory Work, 2.0 credits, grading scale: P, F

Based on recommendation from KTH’s coordinator for disabilities, the examiner will decide how to adapt an examination for students with documented disability.

The examiner may apply another examination format when re-examining individual students.

If the course is discontinued, students may request to be examined during the following two academic years.

Examiner

Ethical approach

- All members of a group are responsible for the group's work.

- In any assessment, every student shall honestly disclose any help received and sources used.

- In an oral assessment, every student shall be able to present and answer questions about the entire assignment and solution.