- terminology and basic theory for modelling and simulation of part manufacturing

- process planning – design and simulation of the manufacturing process in a CAM progra

- flow analysis for estimating production capacity and lead times, identify bottlenecks and decide buffer sizes, using a software for discrete event-driven simulation

- planning of a manufacturing plant in a factory layout system

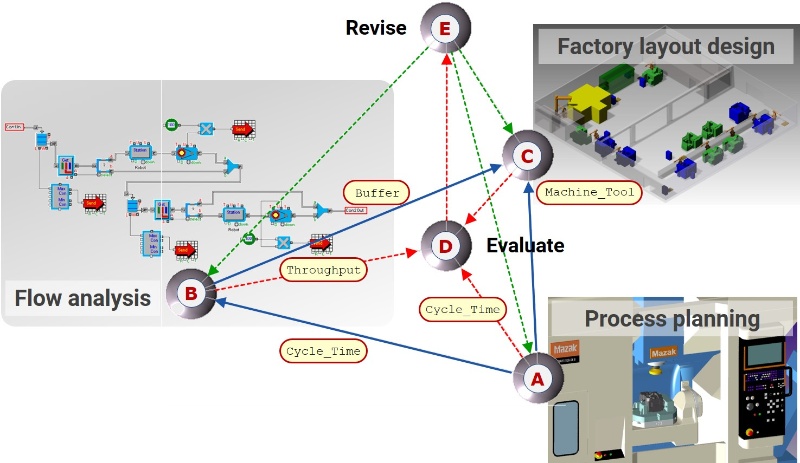

- interaction between process planning, flow simulation and factory layout during development and analysis of a manufacturing system

- modelling and simulation of a complex part manufacturing system, based on given preconditions

MG2130 Modelling and Simulation of Industrial Processes 9.0 credits

In this course you will learn about theories, methods and tools used in development of factories.

Information per course offering

Information for Autumn 2025 Start 27 Oct 2025 programme students

- Course location

KTH Campus

- Duration

- 27 Oct 2025 - 13 Mar 2026

- Periods

Autumn 2025: P2 (4.5 hp)

Spring 2026: P3 (4.5 hp)

- Pace of study

33%

- Application code

50854

- Form of study

Normal Daytime

- Language of instruction

English

- Course memo

- Course memo is not published

- Number of places

Places are not limited

- Target group

- Compulsory for TPRMM, year 1 Elective for all other Master programmes as long as it can be included in your programme. CMAST4, CDEPR4 course within technical profile

- Planned modular schedule

- [object Object]

- Schedule

Contact

Course syllabus as PDF

Please note: all information from the Course syllabus is available on this page in an accessible format.

Course syllabus MG2130 (Autumn 2019–)Content and learning outcomes

Course contents

Intended learning outcomes

After passing the course, the student will be able to:

- describe different types of models used for model-based development and analysis of manufacturing systems

- design and analyse operations for a certain manufacturing process, using a CAM system

- develop and implement a model for discrete event simulation of material flows, when designing and analysing a manufacturing system to be

- use specific factory layout software to plan a manufacturing plant, based on given preconditions and requirements

- analyse interaction and mutual influence between manufacturing process, material flow and the layout of the manufacturing system, during model-based development

- develop a model of a system for manufacturing a given number of an advanced industrial product, including design of process, material flow and layout, based on given manufacturing preconditions

Literature and preparations

Specific prerequisites

MG1016/MG1026 Manufacturing Technology, MG1024 Production,

or the equivalent

Recommended prerequisites

MG1024 Production

or the corresponding

Literature

Examination and completion

Grading scale

Examination

- PROJ - Project Assignment, 4.5 credits, grading scale: P, F

- TENA - Written Examination, 3.0 credits, grading scale: A, B, C, D, E, FX, F

- LABB - Laboratory Exercises, 1.0 credits, grading scale: P, F

- LITT - Log Book Writing, 0.5 credits, grading scale: P, F

Based on recommendation from KTH’s coordinator for disabilities, the examiner will decide how to adapt an examination for students with documented disability.

The examiner may apply another examination format when re-examining individual students.

If the course is discontinued, students may request to be examined during the following two academic years.

Examiner

Ethical approach

- All members of a group are responsible for the group's work.

- In any assessment, every student shall honestly disclose any help received and sources used.

- In an oral assessment, every student shall be able to present and answer questions about the entire assignment and solution.