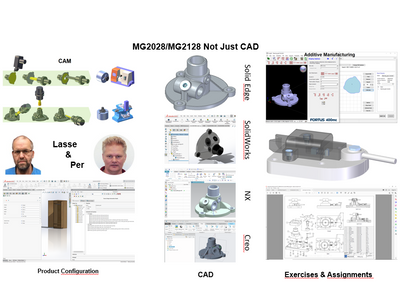

Following an introductory CAD part and a part where CAD skills are developed, the course is divided into different subtasks, each focusing on one type of IT tool used by mechanical engineers in manufacturing industry. Each of these tasks include at least one introductory lecture, or guest lecture dealing with industrial aspects, and one supervised computer laboratory exercise. In addition to this basic computer exercise, and compulsdory homework assignments, the students can opt to take further, more advanced, non-supervised, non-scheduled homework assignments. Much of the work during the course is hands-on, working in our department’s computer lab.

MG2128 CAD and Other IT Tools in Industrial Processes, Extended Course 7.5 credits

Today, manufacturing companies face fierce international competition, where new products have to be developed and produced at an ever increasing pace. Thus, productivity in the product realization process is of uttermost importance. Companies form joint ventures and cooperate with subcontractors and consultants in order to speed up their work. To facilitate such sharing of work tasks, the use of IT tools, such as CAD, CAM, CAE and PDM systems is becoming a necessity. However, in order to fully utilize such tools, well-structured and efficient sharing and exchange of information between the different companies and their software systems are necessary.

In this course, you will learn more about the IT tools used by mechanical engineers, and how information should be created and re-used in a well-structured manner during design, analysis and manufacturing of products.

Information per course offering

Information for Autumn 2025 Start 25 Aug 2025 programme students

- Course location

KTH Campus

- Duration

- 25 Aug 2025 - 12 Jan 2026

- Periods

Autumn 2025: P1 (3 hp), P2 (4.5 hp)

- Pace of study

25%

- Application code

50857

- Form of study

Normal Daytime

- Language of instruction

English

- Course memo

- Course memo is not published

- Number of places

Min: 5

- Target group

- Conditionally elective for TPRMM1

Elective for all 5 year engineering programmes, year 3 and for Master programmes, year 1-2 as long as it can be included in your programme.

Students who have taken the introductory CAD course (MG1028 or as part of MF1061 or MF1001/MJ1103) should take the course MG2028 instead Not for students who have taken MG2028 - Planned modular schedule

- [object Object]

- Schedule

Contact

Course syllabus as PDF

Please note: all information from the Course syllabus is available on this page in an accessible format.

Course syllabus MG2128 (Autumn 2019–)Content and learning outcomes

Course disposition

Course contents

- Introductory CAD

- Guidelines for creating robust CAD models

- IT tools (software) for:

o manufacturing preparation, CAM

o product configuration

o compter aided calculations, FEM and CAE - Other IT tools that utilise the CAD model, e.g. for metrology or preparation for additive manufacturing

- Standards for structuring and exchanging product data

- Work methods and information handling in IT systems for industrial product realization

Intended learning outcomes

After passing the course, the student will be able to:

- create a CAD model in Solid Edge or any similar CAD system as:

- a parameterized part model

- an assembly of part models

- an animated mechanism model

- a fully dimensioned detail drawing of a part

- an assembly drawing with an exploded view and a parts list - in a modern CAD system, create robust models, that could easily be understood and further developed by others

- use CAD models:

- in a CAM system for creating a simple process plan for a part model, and build and use a machine tool model for simulation of the manufacturing process

- in a product configuration system integrated with a CAD system build and use a configuration model

- in a FEM program carry out a simple finite element analysis and simulation of the manufacturing of a part - adapt a CAD model for additive manufacturing and use it in preparation for manufacturing in a given additive manufacturing machine

- create and exchange information about a product and its manufacturing by:

- using CAD system functionality in a structured manner, to communicate CAD related data

- using common exchange formats for product data exchange between different information handling

software systems - indepeendently and in own words reason about:

- how product and production information is handled in manufacturing companies, and how they use IT tools in their product realization processes

- opportunities and problems regarding information handling in an industrial product realization process

Literature and preparations

Specific prerequisites

MF1061 Design and Product Realization, Introduction

or MJ1103 Introduction to Mechanical Engineering/MF1001 Mechanical Engineering, Introductory Course

or the equivalent

Swedish B and English A or the equivalent

Recommended prerequisites

Basic knowledge about product design and production

Literature

Examination and completion

Grading scale

Examination

- INL1 - Homework Assignments CAD, 1.5 credits, grading scale: A, B, C, D, E, FX, F

- INL2 - Homework Assignments other, 3.0 credits, grading scale: A, B, C, D, E, FX, F

- LAB2 - Laboratory Exercises other, 1.5 credits, grading scale: P, F

- LAB1 - Laboratory Exercises Introductory CAD, 1.5 credits, grading scale: P, F

Based on recommendation from KTH’s coordinator for disabilities, the examiner will decide how to adapt an examination for students with documented disability.

The examiner may apply another examination format when re-examining individual students.

If the course is discontinued, students may request to be examined during the following two academic years.

The first intended learning outcome (ILO) is assessed in the module LAB1.

The second ILO is assessed in the modules LAB1, LAB2 and INL1.

The other ILOs are assessed in the modules LAB2 and INL2.

To get a higher grade a number of voluntary assignments have to b completed and approved.

The assessment for higher grades are part of the module INL2.

Other requirements for final grade

CAD exercises must be presented in person in one of our computer labs.

Examiner

Ethical approach

- All members of a group are responsible for the group's work.

- In any assessment, every student shall honestly disclose any help received and sources used.

- In an oral assessment, every student shall be able to present and answer questions about the entire assignment and solution.

Further information

Course room in Canvas

Offered by

Main field of study

Education cycle

Supplementary information

Students who have taken any of the courses MF1046/MF1061, MJ1103/MF1001 or MG1028 should take the course MG2028

This course may not be taken by students who have taken the course MG2028