Research Interests

Aims and Scope of Current Research Program

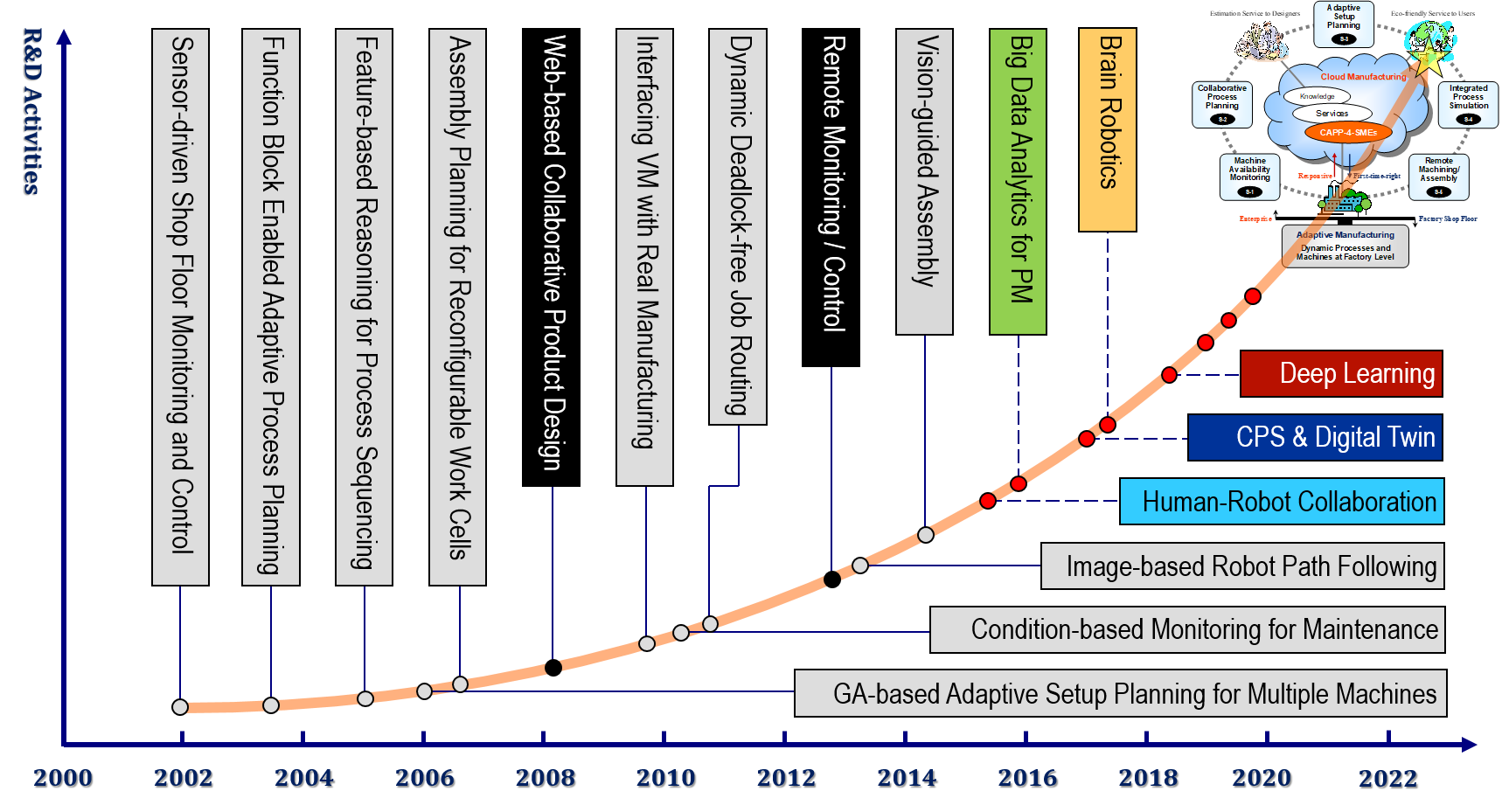

Professor Wang's research aims at generating innovative, adaptive yet practical solutions to solve real-world shop floor problems by applying advanced manufacturing technologies. His research interests are primarily focused on adaptive decision-making methodologies and algorithms from web-based real-time monitoring through adaptive planning to just-in-time control of manufacturing processes and equipment in a decentralised and dynamic environment. With hardware in the loop, his research is also to bridge the gap between virtual manufacturing and real ones, where information can flow freely and bi-directionally between the two. Within the context, computer graphics, artificial intelligence and the latest information technologies are combined with manufacturing science to make adaptive decisions. The scope of this on-going research program is schematically illustrated in the figure below.

Primary Research Topics

- Energy Modelling for Machining and Robotic Operations

- Distributed Process Planning and Execution Monitoring

- Adaptive Setup Planning and Setup Merging

- Dynamic Generative Assembly Process Planning

- Active Colision Avoidance between Humans and Robots

- Human-Robot Collaborative Assembly

- Function Block Enabled Adaptive Machine Control

- In-Situ Dicision Support Systems for Mobile Operators

- Condition-Based Monitoring and Predictive Maintenance

- Web-Based Sensor-Driven e-Shop Floor

- Life-Cycle Engineering and Remanufacturing

- Big Data Analytics and Cloud Manufacturing

- Cyber-Physical Systems in Manufacturing

- Brain Robotics for Assembly

- 4D Printing

Past and Current Research Projects

- ODIN: Open-Digital-Industrial and Networking Pilot Lines Using Modular Components for Scalable Production, EU H2020-ICT-46-2020 Programme, 2021-2024

- Closed-Loop 4D Printing with High Precision, The Swedish Research Council, 2018-2021.

- Research on Operations and Decision-Making Methodologies Based on Dynamic Multi-Scale Data Analysis for Intelligent Workshop, Joint China-Sweden Mobility Programme, STINT (Sweden), 2017-2021.

- SCOR: A Safety Model for Collaborative Robots, Production2030 Programme, Vinnova (Sweden), 2016-2018

- COROMA: Cognitively Enhanced Robot for Flexible Manufacturing of Metal and Composite Parts, EU H2020-FoF-2-2016 Programme, 2016-2019

- SYMBIO-TIC: Symbiotic Human-Robot Collaborative Assembly: Technologies, Innovations and Competitiveness, EU H2020-FoF-6-2014 Programme, 2015-2019

- DYNAMITE: DYnamic humaN AutoMation InTEraction, Production2030 Programme, Vinnova (Sweden), 2014-2016

- SMARTER: Sustainable Manufacturing Adaptive Services with Cloud Architectures for Enterprises, EU FP7-PEOPLE-2013-IAPP Programme, 2014-2017

- CAPP-4-SMEs:Collaborative and Adaptive Process Planning for Sustainable Manufacturing, EU FP7-2012-NMP-ICT-FoF Programme, 2012-2015

- R&D towards Factories of the Future, Strategic Research Fund, University of Skövde, 2011-2012

- Wise-ShopFloor: Towards a Web-based Sensor-driven e-Shop Floor, Knowledge Foundation (Sweden), 2011-2014

- GREENet: Globally Recoverable and Eco-friendly E-equipment Network with Distributed Information Service Management, EU FP7-PEOPLE-2010-IRSES Programme, 2011-2015

- Development of a Conceptual Demonstrator for Distributed Process Planning, Strategic Research Fund, University of Skövde, 2010-2011

- Feature-Based Operation Planning, Application within Strategic Vehicle Research and Innovation Initiative (FFI) Programme, Vinnova (Sweden), 2009-2012

- Reconfigurable and Adaptable Process Plans for Manufacturing, Strategic Project, Natural Sciences and Engineering Research Council of Canada, 2007-2009

- Function Block Enabled Process Planning and Execution Control for Job Shop Operations, Discovery Grant (Individual), Natural Sciences and Engineering Research Council of Canada, 2005-2009

- Intelligent Process Planning System for Optimal Multiple Axis CNC Machining, NRC-A*STAR Collaborative Research Grant, National Research Council Canada, 2003-2006

- Distributed Machining Process Planning for the Dynamic Shop Floor Environment, Enabling Research Grant, Materials & Manufacturing Ontario (Canada), 2003-2005

- Research on Advanced Distributed Planning and Control in Manufacturing, NRC-NSC Collaborative Research Grant, National Research Council Canada, 2002-2005

- Sensor-Driven Remote Monitoring and Control of Networked CNC Machines Using Java 3D, Research Grant, FANUC FA and Robot Foundation (Japan), 2002-2003

- Distributed Process Planning and Control for Reconfigurable Manufacturing, Research Grant (Individual), Natural Sciences and Engineering Research Council of Canada, 2001-2004

- Study on Thermal Behaviour of Machine Tools, Nitto Research Foundation (Japan), 1997

- Multimedia-Supported Machining Technology, Advanced Research & Education Grant, Toyohashi University of Technology (Japan), 1997

- Setup-Less Fabrication Technology, OSG Fund (Japan), 1996

- Automated CAM Technology for Machining, Research Grant (Group), Japanese Ministry of Education, 1996-1997

- Machining Feature-Based Fixture Design and Fabrication, Research Grant (Individual), Japanese Ministry of Education, 1996

Notes to Prospective Students

Graduate students, interested in pursuing a PhD degree in the above research topics or areas related to energy modelling, intelligent automation, human-robot collaboration and sustainability research, are encouraged to contact Professor Wang for more information. Self-motivated and responsible students are welcome. Selection of a PhD student is based on the following criteria.

- Quality: Be knowledgeable and hardworking towards good research performance

- Attitude: Be reliable, responsible, proactive and dedicated

- Ability: Be independent and innovative for problem solving

- Capacity: Can work under pressure and within short due dates

- Leadership: Can lead a smaller team (e.g. supervising under/graduate students, leading a task in a big project, etc.)