Andreas Archenti

Professor

Detaljer

Forskare

Om mig

Professor Andreas Archenti is actively engaged in precision-driven research within the area of machinery reliability and performance. Since 2018, he has held the position of Chair Professor in Industrial Dependability with a particular emphasis on Precision Engineering, Metrology, and Analytics at KTH Royal Institute of Technology. He earned his M.S. in Mechanical Engineering with a focus on Mechatronics in 2007 and completed his PhD in Machine and Process Technology in 2011. In 2014, he was appointed as a docent in Precision Manufacturing and Metrology at KTH.

As the Director of the Center for Design and Management of Manufacturing Systems (DMMS) at KTH, Dr. Archenti is responsible for coordinating activities related to research, education, and the dissemination of information between academia and the manufacturing industry.

Education

- 2011 - Phd in Machine and Process Technology

- 2007 - MSc (Civilingenjör) in Mechanical engineering focusing on Mechatronics

Research interesst

Precision engineering is a strategic process that leverages advanced knowledge, cutting-edge technologies, and innovative methods to develop novel or substantially improved products, systems and services.

Precision manufacturing and integrated metrology involve producing and characterizing a product's dimensions, geometry, and surface properties, as well as measuring, monitoring, and controlling equipment reliability and performance. Today, research in precision-driven manufacturing and metrology spans a wide spectrum, from large components in the aerospace, automotive, and energy industries to micro/nano fabrication for semiconductor or medical industries. Moreover, precision engineering plays a vital role in ensuring the quality of various products, including wafers in lithography, medical devices, and optical equipment. We can see examples of precision manufacturing and metrology in large-scale science projects, such as the alignment of cryomagnets at the Large Hadron Collider (LHC) at CERN and the Laser Interferometer Gravitational-Wave Observatory (LIGO) for gravitational research, or the James Webb whose 132 actuators position the mirrors with 10 nanometer accuracy. But we can also perceive its impact on daily goods, for example in the fabrication of moulds for contact lenses and its posterior measurement and quality assurance.

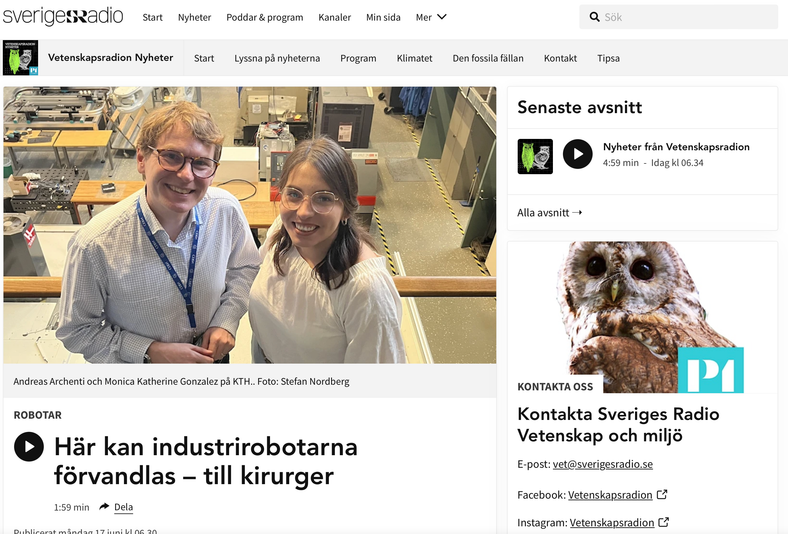

He is currently involved in a research collaboration with the University of Tokyo on robotics for scientific exploration applied to biomedical applications. You can hear more about it in this clip from Swedish Science Radio.

Kurser

Avancerad mätteknik (MG2110), examinator

Avancerad produktionsutrustning (MG2047), examinator, kursansvarig

Avancerad tillverkningsteknik (MG2009), lärare

Avancerad tillverkningsteknik, större kurs (MG2109), lärare

Beslutsstöd för avancerad tillverkning (MG2045), examinator

Examensarbete inom hållbar produktionsutveckling, avancerad nivå (ML230X), examinator

Examensarbete inom hållbar produktionsutveckling, avancerad nivå (ML231X), examinator

Examensarbete inom industriell produktion, avancerad nivå (MG212X), examinator

Examensarbete inom industriell produktion, avancerad nivå (MG213X), examinator

Industriell analys för avancerad tillverkning (ML2306), kursansvarig, examinator

Modern industriell mätteknik (MG2010), lärare, examinator

Vetenskaplig forskningsmetodik inom industriell produktion (MG2100), lärare