Advanced PDMS microfabrication

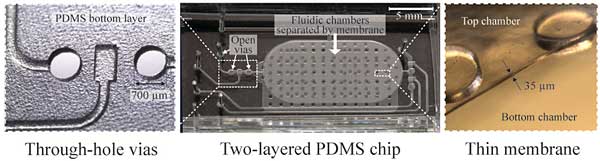

PDMS manufacturing is the most commonly used polymer for rapid prototyping of microfluidic systems, due to its simple fabrication procedure through casting and curing. As microfluidic systems become more advanced, new challenges appear due to limitations of conventional fabrication methods. Examples of features difficult to fabricate are vertical channel connections between polymer layers in multilayer systems and fragile structures such as thin membranes.

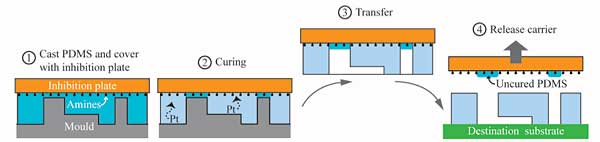

Fabrication of through-holes using polymerization inhibition

Inhibition of PDMS polymerization can be used to achieve open holes at desired sites. After casting of PDMS prepolymer onto a two-height mold, an aminosilane-coated plate is pressed onto the polymer. After curing and transfer, the uncured PDMS at the through-hole sites is removed from the PDMS together with the inhibition plate.

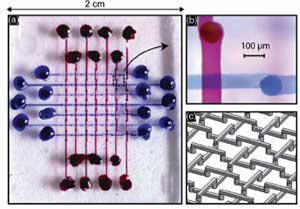

Right: Two-layered basket weave structure fabricated using targeted inhibition of PDMS

Fabrication of fragile layers

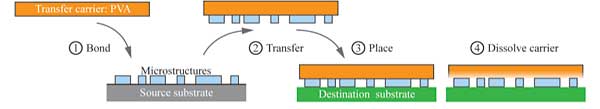

Fragile PDMS structures such as thin membranes are difficult to keep intact during the microsystem fabrication process. The water-dissolvable polymer poly(vinyl alcohol) – PVA – can be used as a release layer to allow low-stress release from the mold and the transfer carrier. In the first method, a PVA film is used as a transfer carrier which is totally or partially dissolved after transfer. The second method utilizes floatation of large PDMS sheets in water for low-stress transfer and assembly.

Transfer using PVA film as carrier: PDMS structures adhere to PVA film during PDMS curing and are thereafter protected by the film during transfer. The film is dissolved using water after the transfer process, which allow low-stress release of the PDMS structures.

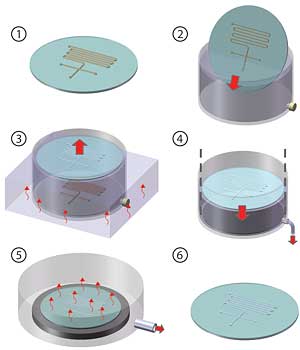

Floatation-based transfer: A wafer-sized mold coated with PVA and cured PDMS PDMS is spun onto a PVA-coated mold, cured (1) and immersed into a water bath (2). Ultrasonication provide PVA dissolution and bubble formation, forcing the PDMS to float from the mold to the water surface. The mold is replaced with a target surface and the PDMS is floated onto this by removing the water (4). Alignment is automatically achieved by matching the bath size with the mold size, and can be further improved by sliding the PDMS on top of a residual water film on the destination surface. Heat and low-pressure treatment is used to remove the last water and achieve bonding. Multilayer assembly is achieved by repeating the steps and using the first system as destination substrate.

Contact information

Sponsors

This work was performed as parts of the EU sponsored FP7 projects Sabio and InTopSens.