Manufacturing and Metrology Systems

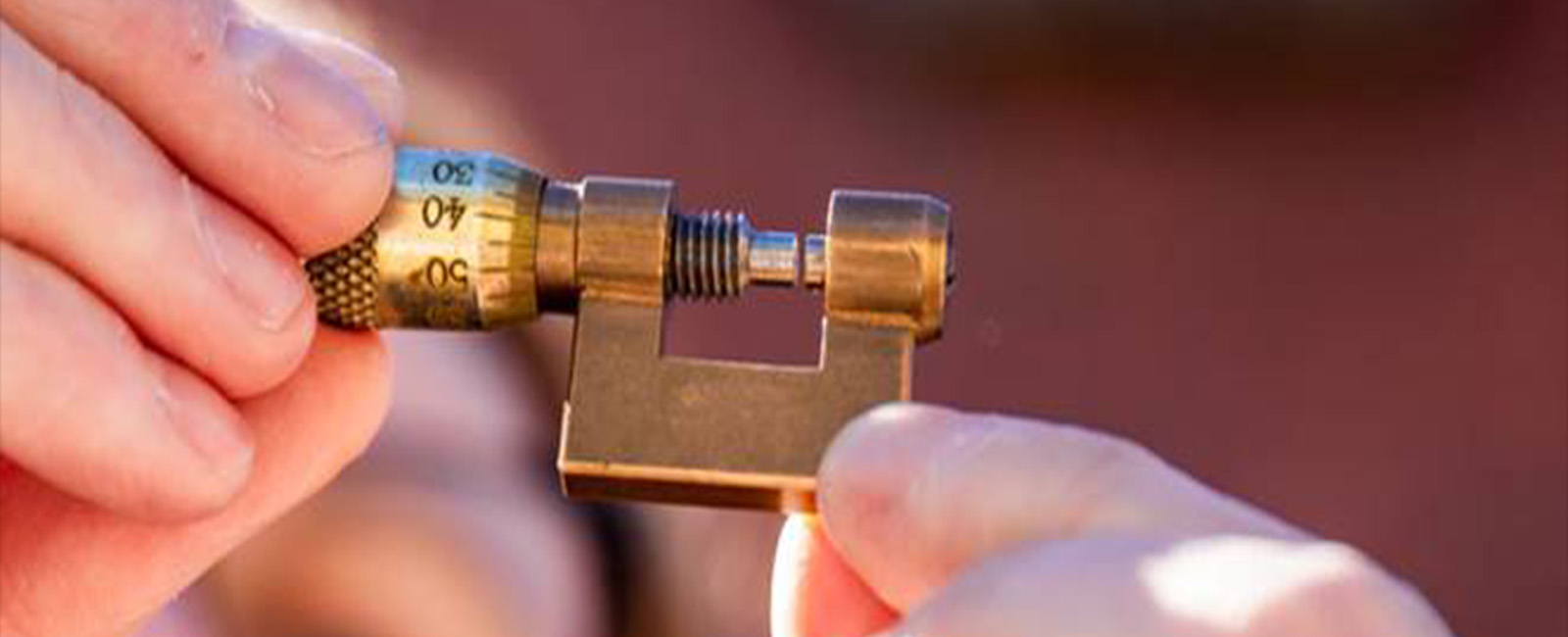

The research within Manufacturing & Metrology Systems is conducted in three fields: Precision Engineering and Metrology, Manufacturing Machines and Processes, and Circular Manufacturing System.

About the research area

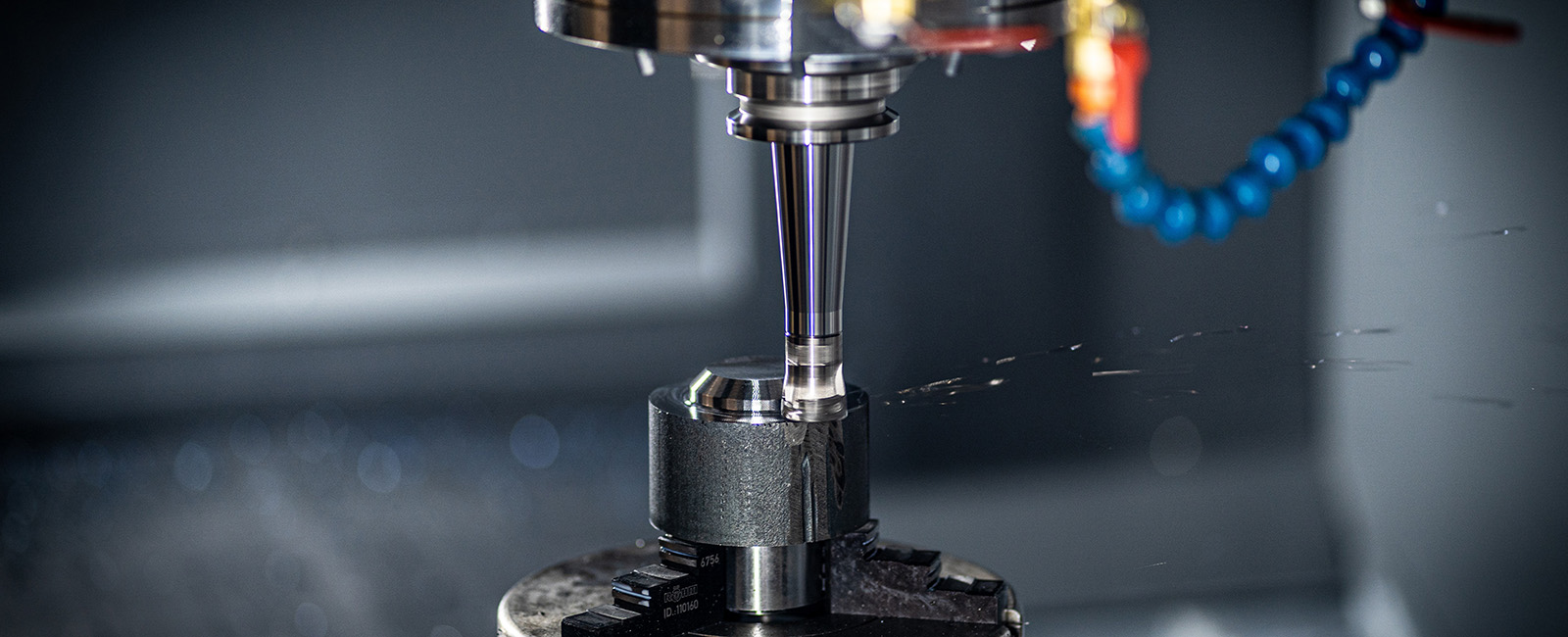

Research and education has strong connection with the aims and objectives of sustainable development and UN’s sustainable development goals. Moving to digital production processes through AM is not only opening new avenues innovation in personalised health through, for example customised implants it is also improving the work environment in production making it cleaner and decent. Research in precision engineering and machine tools on the other hand is boosting innovation in the production environment to enhance productivity and competitive advantage.

Putting all together, the circular manufacturing systems are assuming responsibility beyond the boundaries of production shops aiming to make the industrial systems restorative and regenerative, both minimising waste and environmental footprint of manufacturing industry. The SDGs 3, 4, 8, 9, 12 and 13 are the most relevant and provide a common ground for evaluating the impact and contribution of our engagement in the context of sustainable development.

Research themes

Manufacturing & Metrology Systems

Activities

- How can manufacturing industry, considering product design, manufacturing processes and systems, become more competitive while minimising its environmental footprint?

- How to increase precision, productivity and sustainability on each level of the production, starting from the design, through manufacturing processes to the novel metrology systems?

- How to design and implement manufacturing systems with restorative and regenerative characteristics, meant to design out waste from the industrial environment and support industry in its transition from linear to circular systems?

- What are the parameters for successful (e.g. crack free, dense, geometrically reliable) AM manufacturing, to improve the material performance and to increase the production rate? How can we measure and monitor the corresponding AM parameters? What are the diverse postprocessing requirements in realising fully functional AM components and products?