Multifunctional Materials and Structures

Multifunctional composites

This path of research relates to carbon fibre composites which are in some way electrochemically active and can be used for energy storage, sensing, shape morphing and energy harvesting.

Structural composite batteries

The idea behind this research is to combine a high-performance carbon fibre composite material with inherent energy storage like a Li-ion battery. By having two distinctly different functions in the material itself it is envisioned that substantial mass savings are possible on systems level since the material both carries structural loads and stores electrical energy.

Schematic of a laminated structural battery. The negative electrode is a carbon fibre layer which is separated from the positive electrode consisting of Li-metal oxide coated carbon fibres. The stack is then impregnated with a structural battery electrolyte, a matrix that can both transfer mechanical loads and conduct Li-ions, creating a carbon fibre laminate with inherent energy storage.

Sensing

Carbon fibres become piezo-electrochemical when intercalated with Li-ions. This manifests itself as coupling between the electrical potential between the carbon fibre electrode and its counter electrode when mechanical loads are applied. Mechanical loads cause the cell voltage to change which can be used to sense the load on the carbon fibre composite.

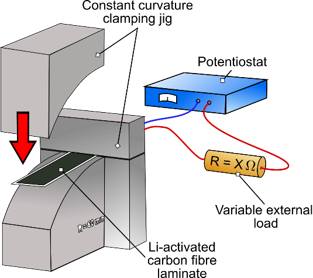

Voltage change between two Li-intercalated carbon fibre layers when bent into a constant curvature, see a video here.

Embedded sensing materials are researched to measure processing conditions during manufacturing as well as health monitoring during use of the composite structure. The picture shows the change in electrical resistivity of composite material doped with carbon nano-particles during strain measurements. Here strain levels are measured contact-free using Digital Image Correlation DIC.

Shape-morphing carbonfibre composites

Carbon fibres expand when being intercalated with Li-ions, and contract during deintercalation. Using this effect one can apply a small current or voltage to make a stiff carbon fibre composite laminate change its shape.

A shape morphing carbon composite laminate created by applying a low electrical potential (<1.5V) between two carbon fibre layers causing one layer to expand and the other to contract, see a video here.

Energy harvesting

By combining the effects of carbon fibre expansion/contraction of carbon fibres and the strain-voltage coupling it is possible to convert mechanical work to electrical power making it possible to make a carbon fibre laminate that can harvest energy.

When the carbon fibre laminate is bent a current will run through an external resistor producing electrical power (left). This is thanks to the strain-voltage response caused by the bending of the laminate. Depending on the resistance of the external electrical load different amounts of electrical power will be generated (right).