Industrial robots learn surgery

Health in fokus

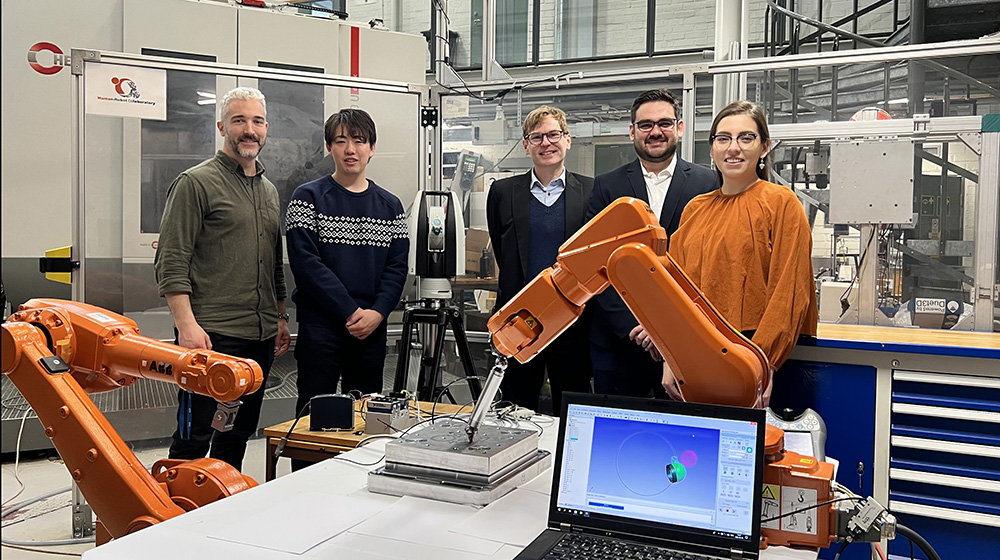

Normally, they are used for heavy lifting and mounting components in factories. Now, KTH researchers are cooperating with the University of Tokyo to enable industrial robots to assist on surgical procedures.

Robot-assisted surgery is a constantly growing practice in hospitals and healthcare institutions worldwide. As recently reported by the news, the first lung transplant using the aid of a robot was performed. It’s reasonable to assume that the application areas in the operating room will expand. Today, the da Vinci robot is one of the world's most widely used surgical robots, with over 5,000 systems installed in hospitals around the globe. But look out, da Vinci, competition is approaching.

“The robots used in industries are robust and fairly cheap since they are manufactured in large volumes and adaptable for many application areas. On top of that, they have high operational reliability. The ones we are currently studying for this collaboration are relatively small and can handle payloads of a few kilos,” says Prof. Andreas Archenti at the Department of Production Engineering.

Improving the accuracy

But, there’s a significant challenge - they have limited accuracy. The researchers are working on finding ways to measure the robot´s positioning errors and apply compensation methods to improve the robot’s accuracy. However, there are still many features missing for it to become reality:

“From the user perspective, researchers still need to address the challenge that involves using haptic technology that can create an experience of touch, which serves as feedback to the operating surgeon.”

Keyhole surgery (or laparoscopic surgery) assisted by robots, presents plenty of benefits over traditional open surgery. Smaller incisions, less blood loss, less pain, faster recovery times, and fewer complications decrease the patient’s time in the hospital. There are also advantages for the surgeon. The surgeon controls the robot sitting in front of a screen; this way, awkward ergonomic positions – or trembling hands - can be mitigated as the robot has much more precise and controlled movements than a human hand. However, current surgical robotics systems are only available in medical centers that can afford the technology and have specially trained surgeons. The utilization of industrial robots can change this.

“If this is accomplished, the potential is great. More patients may have the opportunity to be operated on with this technology,” Andreas Archenti concludes.

Text: Anna Gullers