I-UPS — Innovative High Temperature Heat Pump for Flexible Industrial Systems

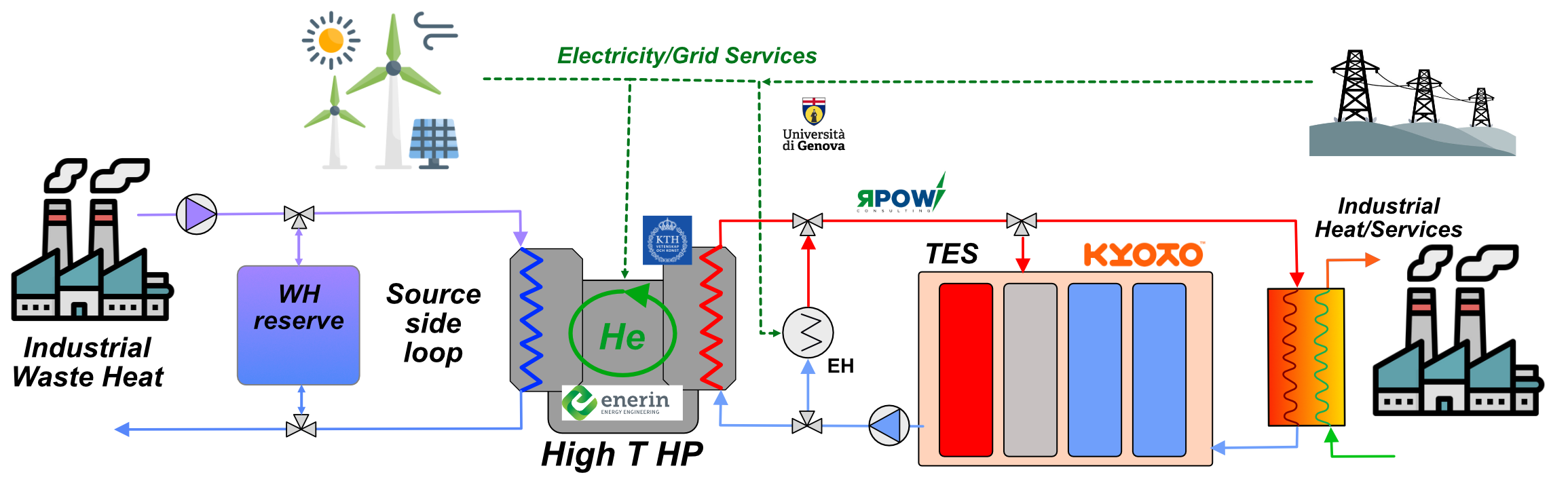

I-UPS aims to develop and validate a first-of-a-kind (FOAK), cost-effective and reliable high-temperature industrial heat pump fully integrated in a flexible energy system for industrial medium temperature (~400°C) heat decarbonisation.

I-UPS validate up to TRL 5 a FOAK high-temperature heat pump, based on Stirling cycles and exploiting a non-toxic, inert, zero ozone depletion potential and zero global warming potential fluid, able to deliver decarbonized heat up to 400°C. No other commercial alternatives are available achieving this heat delivery temperature at efficiencies higher than 100%. The developed heat pump provides enhanced performance thanks to the optimization of key subcomponents, such as optimized static and dynamic sealing solutions and compact heat exchangers enabled by genetic algorithm based design optimization and additive manufacturing techniques. I-UPS provides also a seamless integration of the developed high temperature heat pump in flexible energy systems including molten salts based thermal energy storage (TES) for on-demand decarbonized industrial heat based on RES electricity. The integrated heat pump configuration will enable higher modularity, flexibility, and efficiency for heating decarbonisation also leveraging waste heat recovery and contributing to the circularity of the industrial sector.

Background

Heat pumps powered by low emissions electricity are widely and increasingly recognized as a critical technology for the decarbonisation of the heating sector and a central actor toward a global transition toward a secure, sustainable and affordable heat provision. In 2021, about 10% of space heating needs were met by heat pumps at a global scale. The pace of installation of building and district heating connected heat pumps is growing rapidly. However, such positive trends are not yet reflected or even approached in the industrial sector context. The paper, food and chemicals sectors have been identified as the largest near‐term opportunities for industrial heat pumps installation, with nearly 30% of their combined heating needs which could be addressed even by commercial heat pumps. Only in EU, today, about 15 GW of heat pumps, based on commercially available products reaching maximum heat delivery up to about 150°C, can be installed in more than 3 000 facilities in these three sectors. However, a much broader installation and decarbonization potential could be achieved by developing and bringing to market affordable and reliable heat pump solutions able to deliver heat at temperature higher than 200°C and ensuring larger heating capacities. To fully satisfy the needs of industry, high availability, short payback periods, limited footprint and fast installation are required. It is therefore essential to come up with reliable and cost-efficient solutions for the technological challenges for high temperature heat pumps applications, such as temperature resistant and sustainable materials and subcomponents. Industrial heat pumps are often designed for specific processes and temperature configurations, limiting opportunities to mass produce, which in turns lead to higher design and manufacturing costs and limited opportunities for standardization and growth of market technological acceptance. Large scale electrification of industry and deployment of industrial heat pumps represents a challenge also for the grid operators and grid stability.

I-UPS promotes further development of solutions for high temperature heat pumps and their integration into flexible energy systems for industrial heat decarbonization.

Aim and objectives

The main objective of I-UPS is to develop and validate, at TRL 5, a FOAK cost effective, reliable, and modular high-temperature industrial heat pump fully integrated in a flexible energy system for industrial medium temperature heat decarbonisation. To achieve that the project will:

-

Develop, prototype and validate an innovative, efficient and reliable integrated energy system based on high temperature heat pump for industrial flexible heat provision.

-

Adapt the Stirling cycle based high temperature heat pump architecture and cycle parameters toward operation at high sink temperatures and large temperature lift.

-

Select and validate static and dynamic sealing solutions for pressurized inert gas and molten salts to ensure safe and reliable operation at high temperature.

-

Design and optimize via genetic approaches and prototype via additive manufacturing techniques a cost-effective compact heat exchanger for high temperature heat pump integration operating between pressurized gas and molten salts.

-

Minimize the environmental impact over the full value chain of the proposed heat pump via ‘circularity by design’ approaches and maximize the flexibility of the heat delivered leading to more socially/stakeholders accepted heat pump based industrial integrated solutions.

-

Promote I-UPS solutions across EU a non–EU and facilitate market uptake and path to TRL9 via comprehensive exploitation and standardization roadmaps.

Project partners

Funding is provided by Horizon Europe (CINEA) - Grant Agreement No 101147078.

Timeframe: May 2024 – April 2027