FLEXnCONFU: Flexiblize Combined Cycle Power Plants through Power To-X Solutions using Non-Conventional Fuels

The main goal of the FLEXnCONFU project is to develop and demonstrate innovative, economically viable and replicable power-to-X-to-power (P2X2P) solutions in combined cycle (CC) power plants. The objective is to design and implement integrated power plant layouts that can increase the operational flexibility in order to respond to the electricity demand.

Funded by:

The European Union’s Horizon 2020 research and innovation programme under grant agreement N° 884157

Time period:

April 2020 - December 2025

Project partners:

RINA-C – RINA Consulting

EDP – Energias de Portugal

EDP CNETC – EDP Centre for New Energy Technologies

Cummins (Hydrogenics)

CERTH – Centre for Research and Technology Hellas

Baker Hughes

ETN Global – European Turbine Network

Proton Ventures B.V.

MAS Controlling Power & Energy

CIRCE – Centre of Research for Energy Resources and Consumption

UNIGE – University of Genoa

Cardiff University

TUDA – Technical University of Darmstadt

UCLouvain – Université catholique de Louvain

KTH Royal Institute of Technology

CEA – government technological research organization

TU/e – Eindhoven University of Technology

Tirreno Power

ENGIE Laborelec

UORL – University of Orléans

ICI Caldaie

Project web:

https://flexnconfu.eu/

Background

In its 2030 goals, EU is strongly pushing on renewable energy sources (RES) as well as on alternative fuels to increase EU fuel independency. The achievement of this goal is only possible with a strong integration between conventional power plants and the RES. Combined Cycle Gas Turbine (CCGT) plants will be for the next years the best flexibility sources for compensating the intermittency of the RES. The injection of alternative fuels (i.e. H2 and NH3) will help the current “fuel switch” the EU is facing, drastically reducing CO/CO2/HC emissions, which are more difficult to manage respect to NOx. The P2X solutions, which are currently widely studied, coupled with RES, could help the Combined Cycle (CC) to levelling their load reducing its environmental impact. Hence, developing proper technologies and solutions to couple P2X2P systems with GT is mandatory.

FLEXnCONFU, covering the whole value chain, is a pioneer demonstration to market project, which will contribute to the valorization of European GT and P2G scientific and technological competencies, and to the creation of a clean hydrogen/ammonia society.

Aims and objectives

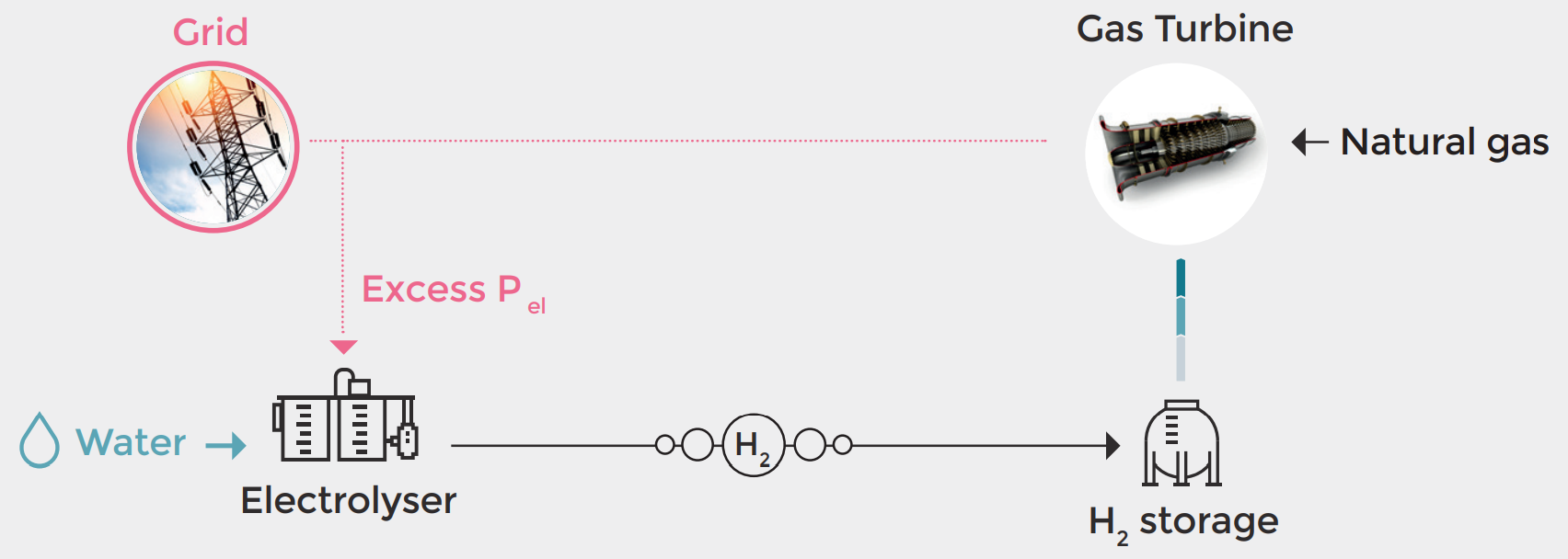

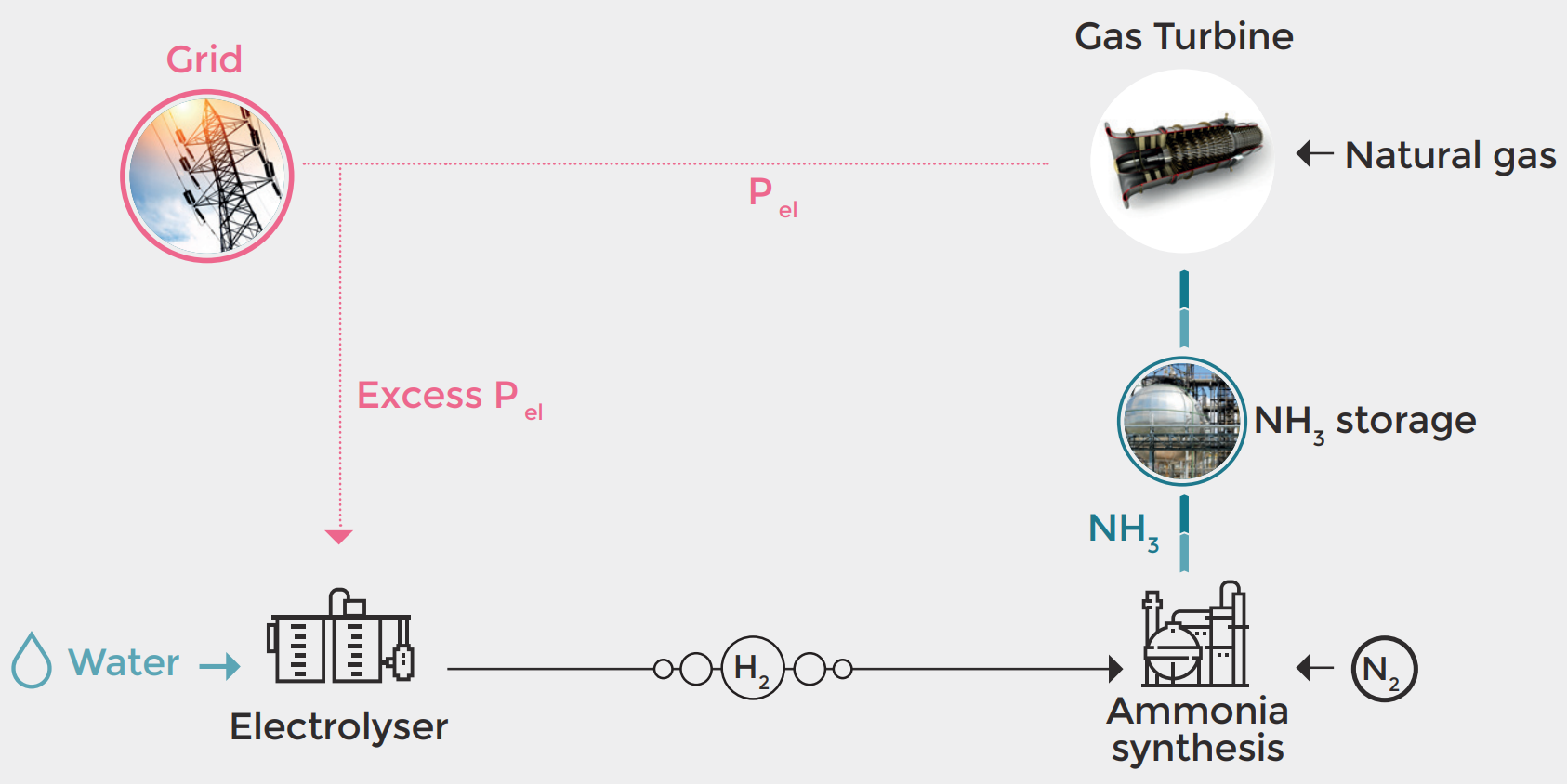

The main goal of the FLEXnCONFU project is to develop and demonstrate innovative, economically viable and replicable power-to-X-to-power (P2X2P) solutions in combined cycle (CC) power plants. The objective is to design and implement integrated power plant layouts that can increase the operational flexibility in order to respond to the electricity demand. This will be done by converting surplus electricity production when demand is low into hydrogen (H2) or Ammonia (NH3). These carbon free fuels can then be converted back to electricity when the demand increases. The power-to-ammonia-to-power system, or P2A2P, will be demonstrated up to TRL6 using a micro gas turbine operating in a smart grid context. This will take place in the laboratory facilities of UNIGE in Savona, Italy. The power-to-hydrogen-to-power system, or P2H2P, will be demonstrated up to TRL7 in an EDP’s real CC power plant in Ribatejo, Portugal. Finally, the replicability of these solutions will be studied in virtual demonstrations sites using techno-economic models developed and validated with data from the physical installations.

Outcomes

The FLEXnCONFU project is articulated in 9 Work Packages (WPs), as shown below. WP1 “Scenario analysis and requirements definition” aims at defining the technical specifications and requirements for FLEXnCONFU layouts, analyzing predicted technical, environmental and economic impacts through a participatory approach by involving GT O&M and energy utilities, while sub-systems specifications and the overall BoP will be outlined and agreed among technology manufacturers. These specifications will be the starting point for the development of FLEXnCONFU subsystems in WP3/4/5. KTH participates in all WPs, however, its largest contribution is to WP1. More specifically, KTH leads task T1.3 “Techno-economic modelling and optimization”. The Principal Investigator (PI) and project leader at KTH is Dr. Rafael Guédez. The PhD student involved in the project is Jose Garcia.

The project is set to work on the following 5 aspects, and the expected outcomes are as follows:

Power-to-Hydrogen, P2H: development, integration and demonstration of a P2H solution (up to TRL7) to increase the CC power plant flexibility and efficiency, while decreasing GHG emissions and use of natural gas. The target is 1000 operating hours for the P2H solution connected with the combined cycle power plant.

Power-to-Ammonia, P2A: demonstration of a P2A solution at lab scale (up to TRL6) using a small-scale ammonia reactor for NH3. Target: P2A system working at T<300˚C and p<35bar.

Publications coming out of this project can be found in FLEXnCONFU’s website (https://flexnconfu.eu/) as part of the dissemination strategy

Project contact persons: