Magnus Wålinder

Professor

Details

Researcher

About me

1. Professional experience

- Since June 1, 2011: Professor in Building materials at

KTH Royal Institute of Technology

School of Architecture and the Built Environment

Department of Civil and Architectural Engineering

Division of Building Materials - Since June 1 2011: Head of the Building materials research group, in November 2023 comprising 15 persons of which 7 senior scientists (1 full-time professor , 1 full-time university lecturer, part-time university adjunct, 3 adjunct professors (20% part time), 1 affiliated faculty (20% part time), 8 full-time PhD students (3 employed, 2 stipends, 3 in industry). In total ca 10 person years.

- 2019 to 2020, Vice Head of department

- Circa 20 years’ experience of wood technology and wood material research and development (R&D)

- 2006–2011 Centre Manager of EcoBuild Institute Excellence Centre, SP Technical Research Institute of Sweden, Wood Technology

- 2004–2006 Head of the R&D group Materials and Products, SP Wood Technology

- 2002–2006 Researcher and project leader, Trätek and SP Wood Technology

- 2002–2015 Split position between SP and KTH (ca 80/20)

- Worked for two years (2000–2002) as postdoctoral research associate at University of Maine, Advanced Engineered Wood Composites Centre (AEWC), Maine, USA

- Editor-in-Chief between 2005 and 2009 and since 2009 Co-Editor, for the scientific journal Wood Material Science and Engineering

2. Academic Degrees: Senior Lecturer (Docent) in Wood and Wood Composites, KTH, 2009; PhD in Wood Technology and Processing, KTH, 2000; Licentiate of Engineering degree (Lic.Eng.) in Wood Technology and Processing, KTH 1996; and Master of Science degree (M.Sc.) in mechanical engineering, KTH 1992.

3. Main teaching activities: AF1301 Building Materials, Basic Course 7.5 credits (Examiner and teacher); AF2301 Building Materials, Advanced Course 7.5 credits (Examiner and main teacher); AF2302 Design of Timber-Based Hybrid Structures 7.5 credits (Examiner and teacher); AI1527 Introduction to the Planning and Building Process 13.5 credits (Momentansvarig).

4. Main research interests: Biobased building materials from renewable resources; wood technology and wood material R&D involving mainly: wood and wood composites material science with a focus on adhesion science and technology, surface science and surface chemistry, wetting phenomena (liquid sorption), gas adsorption/sorption on wood/lignocellulosics and polymers, micromorhology and moisture sorption related to biobased building materials, development of eco-efficient and durability modified wood, wood protection, and wood plastic composites (WPCs). The overall purpose of my research is to support the development of future biobased building materials made from renewable resources. The main challenges for biobased building materials concern their susceptibility for moisture sorption and biological degradation. More efficient manufacturing processes must also be developed to meet the tough competition in the building materials sector.

5. National and international networking: Member of several national, international and European working groups and collaborative forum related to my research field: COST FPS DC Expert, COST FP 1006, SWST, and WSE Northern Euroepean Network in Wood Material Science and Engineering (national coordinator). Akademisk referensgrupp för hållbar samhällsutveckling (KTH).

6. Scientific publications and merits: Has contributed to ca 55 papers in peer reviewed journals or books; 3 editor assignments; and circa 60 papers in proceedings of international conferences, see

See also a compilation of my publications in the DIVA database under the heading Publications (in the right margin at the upper part of this page).

7. Awards:2013: L.J. Markwardt Wood Engineering Award www.forestprod.org/ic/markwardt_award.php)

8. Some remarks on Biobased building material systems

There is an increasing interest in the building sector for new types of eco-efficient biobased building materials. The objective of our research group is to explore the field ofengineered wood and biobased building material systems, primarily based on renewable forest biomass. The over-all aim is to support a sustainable development of the society.

See YouTube presentation about "The New Wood Age" (In Swedish).

Our motto, adopted from Rowellet al. (2010), is:To not use more today than can be replaced tomorrow. This is one of humanity's greatest challenges, not least in terms of the built environment and use of building materials. It is also crucial that heavily forested regions like Scandinavia, with a substantial net growth of the annual forest biomass, is a proactive driving force in this matter.

Examples of emerging and existing bio- or wood-based building materials of interest are so-called biocomposites or wood plastic composites (WPC) and durability-modified wood such as acetylated, furfurylated, thermally modified, and preservative-treated wood. Another potential category is engineered wood products (EWP), e.g. glulam, birch plywood as gusset plates in connections of timber structures. In recent years there has also been a growing interest in the development of timber-based hybrid systems and structures, i.e. composite action on a system level between e.g. wood-based materials and steel or concrete. Growing market segments for such biobased building material systems are multi-storey residential buildings as well as load-bearing long-span structures.

The main shortcomings of bio- or wood-based building materials are related to the high variability of their engineering properties. The combined building products must also have an ability to function during a long time-span, e.g. be dimensionally stable under cyclic climate conditions, and satisfactory withstand mechanical abrasion, microbiological attack and UV radiation. Fire safety is also of great importance. In addition, they also often have to be aesthetically attractive.

Research, teaching and competence development are needed on the composition, microstructure and properties of bio-based building materials in relation to their function and lifespan in various construction applications. One of the biggest challenges is their sensitivity to moisture sorption and biodegradation, i.e. the building materials must not be biodegradable during their in-service life. After this, however, the material system used in buildings and infrastructure should have been designed primarily for purposeful reuse, i.e. a transition or cascading to other uses or products, otherwise they should be recycled, for example by breaking down into new material building blocks, or as a final option, used for energy recovery. Efficient manufacturing processes must also be developed to meet the very tough competition in the building materials sector

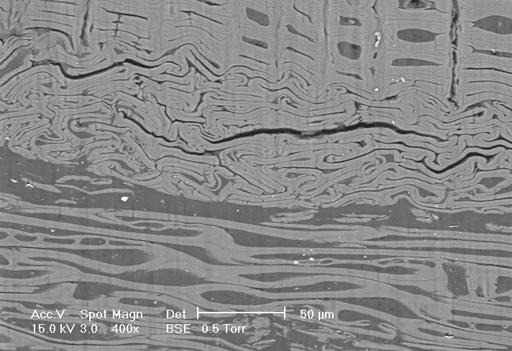

Material refining and modification concepts based on e.g. combined thermal-hydro-mechanical treatments are possible means to ascertain a more predictable behavior of wood- or biobased materials. The micrograph below shows the typical complex micromorphology of a WPC, where the wood component has undergone a quite severe thermal-mechanical treatment.

Scanning electron microscope (SEM) image showing an example of the micromorphology of a wood plastic composite (WPC) where light-grey parts represent wood cell structure, dark-grey parts represent a polyolefin matrix, and the darkest regions represent internal cracks or voids. The wood has in this case been subjected to thermal-mechanical modification resulting in a distinct densification effect of the earlywood tissue (see the mid-region of the micrograph).

Rowell, R.M., Caldeira, F. and Rowell, J.K. (eds.) (2010). Sustainable development in the forest products sector. Fernando Pessoa, Porto, 284 p. ISBN 978-989-643-052-8.

9. On-going and finalized research projects

- Rational building systems for medium to long-span timber structures (2021-24)

- Montageförband på byggarbetsplatsen (2020-23)

- BioInnovation, Outdoor Load-bearing Timber Structures (2017-20)

- EnWoBio - Engineered Wood and Biobased Building Materials Laboratory (2015-19)

- Thermal-hydro-mechanical (THM) modification of wood (2012-14)

See project desriptions below

Some general reasearch areas

- Durability aspects of building materials

- Wood or biobased composites as building materials

- Surface characteristics of wood and wood-polymer compatibility

See more information below regading these projects and research areas:

____________________________________________________

Rational building systems for medium to long-span timber structuresfinanced within Produktion2030 [reference number: 2021-03681], a strategic innovation program supported by Vinnova , Swedish Energy Agency, Formas, coordinated by RISE, including the industry partners Moelven Töreboda AB, Moelven Limtre AS, Rubner Holzbau, Koskisen OY, Dynea AS, Säffle Verkstadsbolag AB, Innovatum, and the Institute of Bioeconomy (Italy).

Project description

The building sector uses the largest share (up to 44%) of global material resources [1]. Its share of energy use and greenhouse gas emission is of the same size. To support a sustainable development of society, there is a great need for new innovative means that can increase the resource efficiency within this sector and reduce its environmental impact. During the last decades, a large and successful effort has been made to increase the energy efficiency of buildings during the user phase, and the interest is now turning towards the material resources and energy use during the production phase.

An increased proportional use of wood as a renewable material in construction could in this case be an important part of the solution, mainly by substituting substantial portions of steel and concrete, which both are non-renewable materials. It is, however, also necessary to find production methods that use the wood material in a more resource-efficient manner. These methods need to be efficient in terms of the amount of material used but also in the ease of factory production and ease of fast and highprecision assembling at building sites. Preferably, the materials will also be easy to recycle at the building end-of-life.

The building process is defined by many actors from different companies that all try to make their part of the value chain resource efficient. For example, assembly of construction elements is normally handled by construction companies, while the construction system is produced by a wood manufacturing company and the fittings are purchased via suppliers. The procedure often involves the use of sub-elements that are not optimal for any of the players in the value chain.

The aim of this project is to explore the potential and possibility of producing a new type of building system for resource-efficient, medium to long-span timber structures. In this case trusses of longer spans, above 15 meters, will serve as an example of a design that can advantageously be divided into standardised modules to simplify and cheapen production, transport, and assembly at the construction site. The goal is to show examples of parts with internal couplings made with digital technology, such as CNC machines and robots.

The specific objective is to develop a system for the manufacture of wood-based elements with an increased degree of bio-based products in constructions, connections and fittings adapted for rational assembly and disassembly of large-span timber structures. The targeted applications are infrastructure such as bridges and public and commercial buildings.

The long-term impact goal of this project is to increase the share of constructions with resource-efficient, bio-based products having a good possibility for reuse. This is done by increasing resource efficiency, predictability and thereby performance, and by mounting the ability of wooden constructions with long spans, which means lower total costs and reduced climate impact. By demonstrating the possibilities of using efficiently produced standardised modules for one project we will also point to the possibility of doing this for other products in the building sector.

_______________

Projektkoordinator: Dr. Lars Blomqvist, RISE

Link to the the project description at RISE:

____________________________________________________

Montageförband på byggarbetsplatsenfinansierat av Familjen Kamprads stiftelse (reference number: 20200013), koordinerat av RISE. Industripartner: Södra Skogsägarnas ekonomiska förening

Projektsammanfattning

Det är brist på i synnerhet billiga bostäder i Sverige. Produktionstakten av bostäder behöver därför öka samtidigt som kostnadsläget behöver minska. Därutöver behöver byggandet bli klimatsmartare. Trä är det byggnadsmaterial som anses bäst ur klimatsynpunkt. Trä passar utmärkt att prefabricera industriellt till en måttnoggrannhetsnivå som vida överstiger vad som är brukligt inom konebtionellt byggande. Trä växer dessutom i vår närhet och är en nationell resurs. Innovationen i det aktuella projektet är att förenkla, förbilliga och förbättra genom att låna och vidareutveckla teknik från en bransch till en annan. Syftet med projektet är att utveckla producerbara självcentrerande beslag färdiga att testas för montage av olika typer av träelement. De förväntade effekterna på längre sikt är att korta tiden och öka precisionen av montage på byggarbetsplatsen och därigenom höja kvaliteten i utförandet, öka effektiviteten på byggplats och därmed reducera den totala byggkostnaden.

Projektkoordinator: Dr. Lars Blomqvist, RISE

Länk till projektbeskrivning vid RISE:

https://www.ri.se/sv/vad-vi-gor/projekt/montageforband-pa-byggarbetsplatsen

________________________________________________

Project period: 2015-19. Main financing from the the Swedish Research Council Formas (no. 2014-172), co-financed by Träcentrum Norr (TCN), Träskyddsföreningen, Ofk Innovation, and RISE (former) SP Technical Research Institute of Sweden; IVL; and also supported by KTH Royal Institute of Technology and LTU Luleå Technical Unicersity.

Aim and objectives

The aim of this project and research platform is toconduct research with the highest international class to produce new knowledge that will contribute to the development of production, use and further refining of renewable forest or agricultural biomass. In particular, this is of a strategic relevance for the present and future biobased building materials industry in Sweden.

The over-all objective is toengineer innovative wood and biobased building materials for the future sustainable society.

The specific objectives comprise the following interacting work packages (WP):

- New biocomposites: a new group of building materials refined from renewable resources based on wood or natural fibres and biopolymers or recyclable thermoplastics with a high potential regarding both eco-efficiency and increased moisture resistance and extended service life, also including load-bearing building material applications.

- New natural wood modification: new concepts based oncombined mechanical-hydro-thermal procedure. Such modified wood is expected to exhibit higher surface hardness, abrasion resistance, dimensional stability as well as increased decay resistance compared with unmodified wood.

- Physico-chemical and moisture analysis of biobased building materials: Moisture sorption is a particular critical feature of biobased materials. Fungal decay resistance, dimensional stability, mechanical performance and insulating capacity of biobased materials are examples of other properties which are affected by moisture.

- Engineered wood products for the construction market: The contemporary construction market is facing new demands to obtain energy and cost efficient building processes. In sustainability perspective biobased products imply a potential alternative in many applications and so-called engineered wood products (EWP) show versatile properties and potential efficiency, which can support the needed societal development.

- LCA and ecological-socio-economical aspects of biobased building materials: A central part of the project also covers a proactive work to draw a strategic roadmap for sustainable innovations for biobased building materials.

- Wood and biobased building materials demonstration sites: Another central part of the project is to demonstrate different biobased material systems by exposing and monitor them in various experimental building materials sites.

Project vision

Within ten years the proportion of wood and biobased building materials used in the building sector, both in Sweden and globally, will increase to a level which supports a sustainable development of the society

To reach this vision it is necessary to create long-term education and research links with essential groups of future decision makers. The target group in this project is engineering students and graduates within the Civil and Architectural Engineering programs at the Swedish Universities of the Built Environment (SBU).

Project strategies

The main strategy to create these links is to increase the visibility of the wood and biobased building materials related industry at these programs which in this project will be accomplished through:

- Split positions for 5-6 PhD students between universities and industry or institute (co-financed by the industry and institute). The goal is to reach engineering licentiate (Tekn. Lic.) examination, or alternative, from Tekn.Lic to the PhD for these students within the project period.

- Close links between the PhD student projects and the building material related classes within these programs.

- Close links between the PhD student projects and the building material related diploma works within these programs.

The project is structured in two interacting research areas: I) biobased building material science, revolving around material analyses and modification; and II) engineering and demonstration of the material systems, including life cycle and sustainability assessment as measures of e.g. environmental and socio-economic consequences. The work will be executed by a multidisciplinary approach in six work packages fitted in a matrix structure, where material science meets the engineering and demonstration areas.

Research team

Prof. Magnus Wålinder (KTH, project leader, WP1 & 3 leader); Prof. Dick Sandberg (LTU, WP2 leader); Dr. Andreas Falk (KTH, research coordinator, WP4 leader); Dr. Martin Erlandsson (KTH/IVL, WP5 split leader); Dr. Anders Bystedt (SP/LTU, WP 5 split leader); Dr. Kristoffer Segerholm (SP/KTH, WP6 leader); Dr. Kristiina Laine (KTH, Posdoc WP2 & 3); Dr. Maziar Sedighi Moghaddam (SP/KTH, Postdoc WP3); Olof Frisk (KTH/Ofk Innovation, PhD student WP1); Benedikt Neyses (LTU, PhD student WP2); Susanna Källbom (KTH, PhD student WP3); Magnus Larsson (KTH, PhD student WP4); Diego Peñalosa (SP/KTH, PhD student WP5); Emilia Markström (SP/LTU, PhD student WP5).

Summary

The objective is to engineer innovative wood and biobased building materials derived from renewable forest or agricultural biomass. The main driving force for this is to support a sustainable development of the society.

A great challenge, however, lies in ensuring long-term consistent performance of biobased building materials under the influence of e.g. hydrothermal variations, UV light, and microbial agents. In many cases a significantly extended service life should be targeted to be competitive to other mineral based materials. In most building applications a biobased material must resist bio-degradation, mainly determined by their moisture resistance.

The materials in focus are biobased composites (biocomposites), naturally modified wood, biobased insulation and cross-laminated timber (CLT) systems. The main idea is to demonstrate new innovative combinations of the materials in various applications, for example in multi-storey timber buildings. The project is structured in two interacting research areas: I) biobased building material science, revolving around material analyses and modification; and II) engineering and demonstration of the material systems, including life cycle and sustainability assessment as measures of e.g. environmental and socio-economic consequences.

The infrastructure for the project consists of a research joint venture between Royal Institute of Technology (KTH), Luleå Technical University (LTU), SP Technical Research Institute of Sweden and a number of industry parties, hosted by KTH.

Sammanfattning

Målet är att utveckla innovativa trä- och biobaserade byggmaterial från förnybar biomassa från skogs- eller jordbruksråvaror. Den främsta drivkraften är att stödja en hållbar utveckling av samhället.

En stor utmaning handlar om att säkerställa biobaserade byggmaterials långtidsprestanda under påverkan av t.ex. hydrotermiska variationer, UV-ljus och mikrobiologisk exponering. I många tillämpningar bör en betydligt förlängd livslängd eftersträvas för att biomaterialen skall vara konkurrenskraftiga jämfört med främst mineralbaserade material. I många byggtillämpningar måste därför ett biobaserat material ha ett säkerställt motstånd mot biologisk nedbrytning, vilket huvudsakligen bestäms av deras fuktegenskaper.

Material i fokus är biobaserade kompositer (biokompositer ), naturligt modifierat trä, biobaserad isolering och system för krysslimmat trä (CLT ). Grundtanken är att demonstrera nya innovativa kombinationer av biobaserade material i olika tillämpningar, till exempel i flervåningshus med trästomme. Projektet är uppdelat i två samverkande forskningsområden: I) materialvetenskap för biobaserade byggmaterial, inriktat mot materialanalyser och trämodifiering; och II) ingenjörsmässig demonstration av de olika materialsystemen, inklusive livscykelanalys (LCA) och hållbarhetsbedömning som mått på t.ex. miljömässiga och samhällsekonomiska konsekvenser.

Infrastrukturen för projektet består av forskningssamverkan mellan Kungliga Tekniska Högskolan (KTH), Luleå Tekniska Universitet (LTU), SP Sveriges Tekniska Forskningsinstitut och ett antal industriparter, med KTH som värd.

____________________________________________________

Thermal-hydro-mechanical (THM) modification of wood (2012-14)

Financed by the Nils and Dorthi Troëdsson Foundation

Research team:PhD student Susanna Källbom (KTH Building materials), Prof. Magnus Wålinder (KTH Building materials), Dr. Kristoffer Segerholm (SP Wood Technology and KTH Building materials), Dr. Dennis Jones (SP Wood Technology) and Prof. em Roger Rowell (Guest Professor at EcoBuild/SP Wood Technology and KTH Building materials).

Aim and objectives

The over-all aim is to research and develop new concepts for biocide free modification of wood for exterior building applications. Product categories of special interest are so-called engineered wood products (EWP) and bio- or wood-based composites for the building envelope and various outdoor applications, e.g. sidings or roof systems, windows, doors, and decking and railing. Service life and durability aspects of such biobased building materials are mainly related to properties such as moisture resistance, dimensional stability, resistance to biological deterioration, hardness, abrasion resistance and weathering features.

The objective is to apply and study concepts based on so-calledthermal-hydro-mechanical (THM) modification of wood, including both solid wood as well as wood residuals (e.g. a ground wood component). The manufacturing processes for the final building material products could either be based on 1) compression, or 2) thermo-forming such as profile extrusion or injection molding. One idea is to apply process conditions where higher moisture levels are allowed in the wood compared to today's conventional processes.

As a specific project objective, state-of-the-art inverse gas chromatography (IGC) will be used to study physico-chemical properties of thermally and THM modified wood. By this approach, new THM modification routes, including also effects of potential processing or modification additives, can be studied. Of special interest are surface energetics related to moisture sorption properties of the modified wood, and also its compatibility with other materials. Such information could also enable tailoring of new compatible material combinations for e.g. wood-based composites.

See the Licentiate Thesis by Susanna Källbom available at Diva regardning this projects:

_________________________________________________

Durability aspects of building materials

This research area aims at a greater understanding of building materials composition, microstructure and properties, and the link to their function and service life in different applications. An expansive area is so-called "green" materials, such as modified wood and biobased composites, adhesives and coating systems. The main challenges for biobased building materials concern their susceptibility for moisture sorption and biological degradation. More efficient manufacturing processes must also be developed to meet the tough competition in the building materials sector.

_______________________________________________

Wood or biobased composites as building materials

One focus in this research area includes new efficient tools for studying the micromorphology of new types of modern and eco-efficient wood based materials. So-called micro machining using UV-laser irradiation has been developed as a suitable surface preparation technique for microscopy.

_______________________________________________

Surface characteristics of wood and wood-polymer compatibility

The scientific focus of this research area includes adhesion science and technology with the main objective to achieve a better understanding of the molecular interaction and adhesion phenomena between wood or biobased materials and other materials. Such information is, in turn, valuable to improve bonding between wood and adhesives or coatings, and also between the constituents in wood-based composites, especially under moist conditions.

Courses

Building Acoustics (AF2404), teacher, examiner

Building Acoustics (AF244V), examiner, teacher

Building Materials, Advanced Course (AF2301), teacher, course responsible, examiner

Building Materials, Basic Course (AF1301), examiner

Degree Project in Building Materials, Second Cycle (AF233X), course responsible, examiner

Degree Project in Built Environment, First Cycle (AF102X), teacher

Design of Timber-Based Hybrid Structures (AF2302), teacher, examiner

Introduction to the Planning and Building Process, Minor Course (AI1531), teacher

Wood durability (AF234V), examiner, course responsible