Peter Hedström

Professor

Details

Researcher

About me

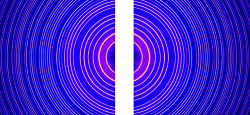

Peter Hedström is Professor in Materials Science at the Department of Materials Science and Engineering at KTH. He heads the Hultgren Laboratory for Materials Characterization, one of four research units at the Department. His PhD degree is from Luleå University of Technology and after working at the metallurgical research institute MEFOS (currently Swerim) he joined KTH in 2008. The research at KTH encompasses advanced materials characterization, structure-property relations in engineering materials, materials design, deformation of metals, phase transformations , powder metallurgy and artificial intelligence for materials science. A key activity within materials characterization is development and application of large-scale research infrastructure (synchrotron x-ray and neutron) methods. Related to this, Hedström is the Director of the Center for X-rays in Swedish materials science (CeXS), which hosts the Swedish Materials Science beamline (P21) at the synchrotron source PETRA III, and he is also the Director of the Vinnova competence center NEXT (Neutron and X-ray science for industrial technology transitions (NEXT) | KTH). Hedström's research is focused on metallic alloys, in particular steels, but he also works on ceramics and composites. Hedström is furthermore active in bringing materials research into innovations and he has co-founded two companies Ferritico and Scatterin, based on research conducted by him and collaborators at KTH.

Selected current activities and projects

|

|

The Vinnova The Vinnova Sustainable Industry competence centre, NEutron and X-ray science for industrial Technology transitions (NEXT), will co-create materials innovations for enabling sustainable industry transitions – using large scale neutron and synchrotron infrastructures (LSIs) as an enabling technology. |

|

The Center for X-rays in Swedish Materials Science (CeXS) hosts the Swedish beamline (P21) at the PETRA III synchrotron source in Hamburg, Germany. The Swedish beamline and the PETRA III synchrotron facility are key in numerous projects in the group. |

|

Hedström and collaborators have been working on low temperature embrittlement of bcc-/bct-containing stainless steels for more than a decade. Currently a larger EIT Raw Materials project ENDUREIT focus on developing improved duplex stainless steels with longer life time in applications such as pressure vessels in chemical and nuclear industry. |

|

|

The center for Mechanics and Materials Design (MMD) is a joint initiative between the Departments of Materials Science and Engineering and Solid Mechanics. The initiative aims at speeding up the processes for producing better materials. Currently one PhD project and one post-doc project in the group is funded through MMD. |

|

|

Neutron scattering has become an important tool in the materials characterization toolbox over the last years for the group. Currently two PhD students are within the SwedNess graduate school, and one institute PhD student focus on neutron scattering characterization. Neutron scattering also contributes significantly to other projects such as ENDUREIT, Hero-m 2i, etc. |

|

|

Additive manufacturing (AM) is a transformative manufacturing technology receiving significant attention currently. In the RÅC project Track-AM led by Greta Lindwall we try to develop an electron-beam additive manufacturing sample environment that will be used to study metal-AM at the PETRA III synchrotron and the P21.2, P07 and P61 beamlines. The group also has one post-doc project on Mg-AM and one on SS-AM. |

|

|

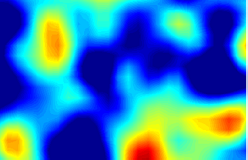

Machine learning (ML), a sub-field of artificial intelligence, shows excellent capabilities in modelling within Materials Science and Engineering. And, our group has been exploring this field. Currently, one visiting PhD student is working on modelling of stainless steel and one visiting student will be working on ML for large-scale infrastructure analysis. Furthermore, we collaborate intensively with the startup Ferritico to develop models, for example in the project ENDUREIT. |

|

|

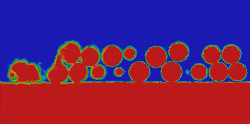

The group has a strong interest in cemented carbide or hard metal research. At the moment one PhD student is working on the sintering of hard metals and another PhD student explores neutron scattering characterization of hard metals. Both these PhD students contribute to the Sintering of non-homogeneous cemented carbides for enhanced performance project supported by a SSF grant. |

Research areas of interest

#MaterialsDesign, #PhaseTransformations, #StructurePropertyRelations, #MachineLearning, #Synchrotron, #Neutron, #MaterialsCharacterization, #Steels, #HardMetals, #CementedCarbides, #Diffraction, #X-rays, #Scattering, #AI, #Metals, #ElectronMicroscopy, #SEM, #TEM, #EBSD, #SANS, #SAXS, #WAXS, #3DXRD, #GrainMapping, #AdditiveManufacturing, #AM, #in-situ, #Micromechanics, #Fatigue.

Courses

Degree Project in Materials and Process Design, Second Cycle (MH201X), examiner

Degree Project in Materials and Process Design, Second Cycle (MH202X), examiner

Experimental Methods (MH2000), teacher

Introduction to Materials Characterization (MH1041), examiner

Materials Design I (MH1030), teacher, course responsible

Materials Physics (MH1026), examiner

Materials Properties II (MH2060), teacher, course responsible