Silk Tube Formation

Spider silk is an incredible material that thanks to its combination of unique properties; high tensile strength, high elasticity, and biocompatibility, has found its way into a multitude of biological applications within the last decade. One of the areas where spider silk has shown great promise is tissue engineering, where it, for example, is used to create tubular structures to imitate and replace blood vessels.

So far it has been shown that it is possible to generate free standing silk tubes oft thicknesses between 150 – 400 μm using dip coating, gel spinning, and electrospinning. While there are mechanically stable, their thickness makes them non-ideal for applications involving cell to cell communication between cells growing on the outside and the inside of the tubes. In order to establish such communication the sheets need to be a few microns thick. However, silk structures of this thickness require some kind of support, generally making one of the sides inaccessible to cell growth.

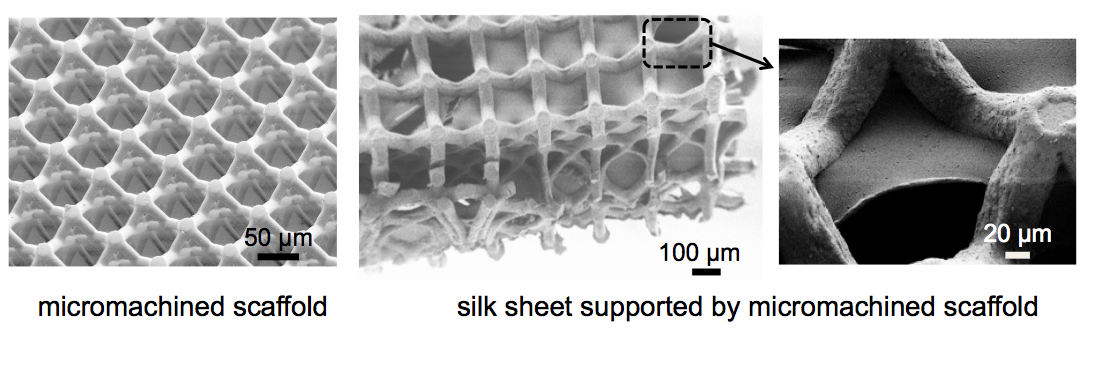

In this project we utilize a micromachined scaffold to support the thin silk sheet. In short porous micromachined scaffold is inserted into soluble silk protein that transforms into silk during evaporation (see Structuring Spider Silk for more information). This leads to that a silk sheet forms in the openings of the scaffold, fully encapsulating it. The scaffold supports the thin sheet, allows for cell-to-cell communications in the openings, and is accessible from both the inside and the outside.

Learn more about this work by checking out this video. You can also learn more about the formation of the micromachined scaffold on this page.

------------------------------------------------------------------------------------------------------------

Project Members:

Linnea Gustafsson, Weijin Guo, Ronnie Jansson, My Hedhammar, and Prof. Wouter van der Wijngaart

Publications related to this project:

Formation of a thin-walled Spider Silk Tube on a Micromachined Scaffold

Project Sponsors:

Swedish Research Council (VR), Knut and Alice Wallenberg Foundation (KAW), and the European Union’s Horizon 2020 research and innovation program under the Marie Skłodowska-Curie (ND4ID)