Research Projects

Current Research Projects

Biocatalytical cascades for the surface functionalisation of lignocellulose fibres

Lignocellulosic fibres are attractive materials that can replace traditional fossil-based products due to their unique functional properties. This project proposes a radical approach integrating enzyme technology and material sciences for the production and surface functionalization of cellulosic fibres from woody biomass, exploiting the biochemical diversity and biological role of hemicelluloses in plant cell walls. This project will provide a novel nature-inspired biocatalytic platform to functionalize lignocellulosic fibres with increased material yields and reduced chemical use, which could open new avenues for the subsequent modification of plant fibres tailored to virtually any application.

Funded by the Swedish Research Council Vetenskapsrådet.

Enzymatic

Previous Research Projects

EDIBLE: Better Bound than Free

Our shift to a more sustainable and healthy food system requires increasing the content of plant-based foods rich in dietary fibres and phenolics. This project will develop a new generation of functional food ingredients using cell wall polysaccharides and polyphenols from agricultural side streams, combining the material properties of the polysaccharides and the antioxidant properties of polyphenols. This project clearly contributes to a more sustainable and healthy food system, increasing the availability of dietary fibres and polyphenols in our food products and mitigating food losses exploiting abundant by-products from agricultural production.

Funded by the Novo Nordisk Foundation

BioUPGRADE - Biocatalytic upgrading of natural biopolymers for reassembly as multipurpose materials

The BioUPGRADE action channels functional genomics and material science advances, to transform nature’s major structural polymers into a cascade of high volume and specialized bioproducts, thus tackling climate change while revolutionizing the sustainability of materials used in our daily lives.

FET-Open. This project has received funding from the European Union’s Horizon 2020 research and innovation programme under grant agreement No 964764.

Molecular Basis of the Interactions and Recalcitrance of Lignocellulosic Biomass

Lignocellulosic biomass represents the main renewable resource from the biosphere for the production of biofuels, platform chemicals and bio-based materials. Lignocellulose consists of a complex polymeric network of cellulose microfibrils embedded in a matrix of hemicelluloses, pectins, and lignins with exquisite organization from the nano- to the microscale. However, the heterogeneity of the lignocellulose polymeric components, their strong supramolecular interactions and architecture are responsible for their recalcitrance against biotechnological exploitation. The overarching aim of this research program is to decipher the molecular origin of lignocellulose biomass recalcitrance towards hydrothermal fractionation and enzymatic saccharification. This project will contribute to an improved utilization of biomass resources through the design of energy and material efficient biorefinery processes.

Funded by Vetenskapsrådet.

SYMBIO - Engineering cereal dietary fibre gels for encapsulation of probiotics

Cereal processing generates large volumes of by-products, namely the bran layers that surround the starchy endosperm. Cereal brans still have limited applications for human nutrition due to their recalcitrant nature, poor organoleptic properties and lack of digestion by the human gastrointestinal tract. However, cereal brans contain valuable biomolecules, such as dietary fibres and phenolics, with great potential in multifunctional food products. In this project we will engineer dietary fibre hydrogels from cereal by-products using oxidative enzymes to be used as symbiotic carriers of probiotic bacteria. These symbiotic dietary fibre gels contribute to an effective use of resources and a circular food system. Moreover, they have large potential to be used in innovative and healthy food products modulating the gut microbiota, contributing to mitigate the risks of chronic diseases.

Funded by Formas - A Swedish Research Council for Sustainable Development

FUNGUSCHAIN - Valorization of mushroom farming by-products into high value products

Each year, the European Union produces around 90 million tonnes of food waste, 38% of which is directly produced by the food-manufacturing sector. If we focus on the mushroom farming industry alone, each week more than 60,000 tons of mushroom disregarded outputs are generated in Europe. These are basically treated as an unwanted by-product and used for low value applications. There are, however, major opportunities to turn these outcomes into high value products and this is exactly what the FUNGUSCHAIN project aims to do, by setting up innovative processes in a new biorefinery.

FUNGUSCHAIN will make use of new cascading processes to extract high value molecules from the fungal residue following the requirements of a range of end-users. A first extraction will yield antimicrobials & antioxidants, proteins, polyols and polysaccharides. Further processing will complete the value chain for delivering cleaning, food and plastic products. The remaining residues will be used for composting or biogas synthesis, thus closing the agricultural cycle.

Funded by Horizon 2020 - BBI JU

See press release: An innovative biorefinery will process and transform mushroom farming by-products into high value products

På svenska: 110 miljoner för att omvandla svampavfall till produkter

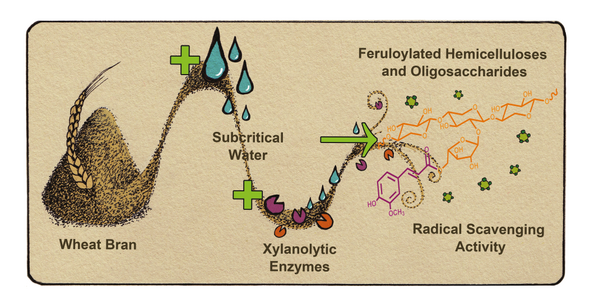

Biobased Multifunctional Materials and Additives from Cereal Byproducts

Cereal production generates high volumes of low value byproducts rich in valuable polysaccharides and phenolic moieties that are currently infrautilized. In this project we will develop multifunctional biobased materials and additives using isolated biomolecules from the bran, husk and straw of wheat, barley and oats. This project will provide the fundamental knowledge to establish a value chain from cereal byproducts to carbohydrate-based products with high value and multiple functionalities, contributing to a smart use of renewable resources.

This project is carried out in collaboration with Chalmers Industrial Biotechnology, Lantmännen and Novozymes.

Funded by Formas - Program on forest and biomass raw materials - and Lantmännen Research Foundation.

Picture by Calle Krantz

Biopolymers with advanced functionalities for building and automotive parts processed through additive manufacturing (BARBARA)

The aim of BARBARA project is the development of novel bio-based engineering materials for validation in functional prototypes with advanced properties for building and automotive sectors. The project will valorize side-stream fractions from agro-food production into novel polysaccharides and functional additives. The extracted polysaccharides will be compatibilised with polyesters and polyamides and reinforced with extracted, modified and functionalised additives to obtain engineering bioplastic formulations adapted to current Fused Filament Fabrication (FFF) processes. The BARBARA project includes 11 partners that encompass the whole project chain, from suppliers of food and farming waste to construction and automotive end-users key to validating those demonstrator pieces.

KTH role in the project involves the development of bioprocesses for the extraction and fractionation of polysaccharides from by-products of corn kernel processing, and their chemo-enzymatic modification.

See press release