Driving fossil-free industry with next-gen nuclear energy

Energy in focus

KTH researchers are working to help heavy industry transition to fossil-free operations. A new initiative in nuclear technology focuses on next-generation reactors to provide efficient electricity and, more importantly, industrial heat.

Nuclear energy has long been a controversial topic in Sweden, but perspectives are shifting. Global tech giants like Google, Amazon, and Microsoft are exploring small nuclear reactors to secure fossil-free electricity, while small modular reactors (SMRs) are increasingly highlighted as a key solution for the future.

Why the shift? Climate change demands urgent action, energy prices are climbing, and advancements in technology have made reactors safer and more efficient.

"Above all, nuclear energy offers a viable solution for achieving a fossil-free transition," says Pär Olsson, Professor of Nuclear Engineering at KTH Royal Institute of Technology. "The transport sector is moving toward electrification, and Sweden already has low emissions from electricity production. Our biggest challenge today is addressing the energy needs of heavy industry."

Fossile-free solutions

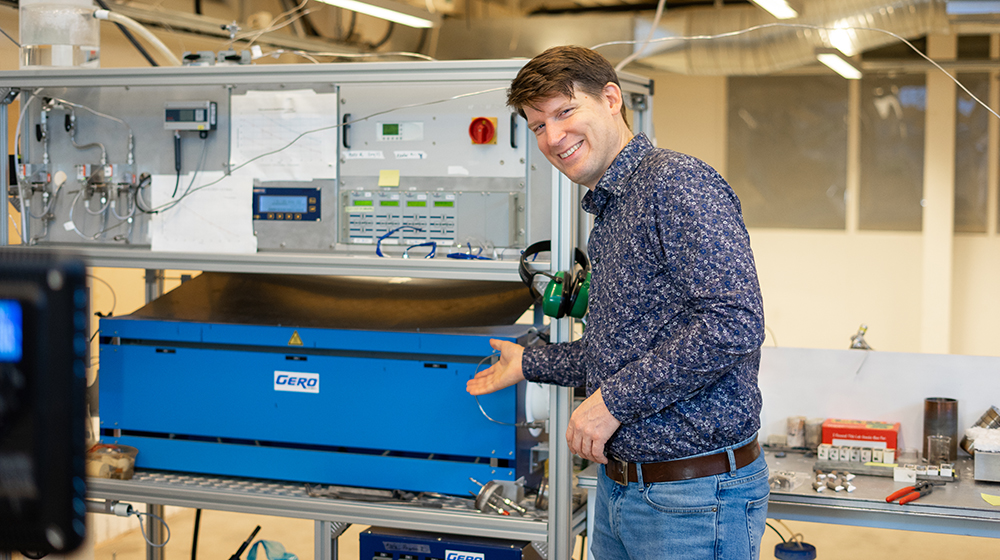

Olsson leads a new strategic initiative at KTH aimed at helping industries adopt fossil-free solutions powered by nuclear energy.

"This isn’t about replacing solar or wind power—it’s about creating a mix of fossil-free energy sources. Heavy industry requires a steady, continuous energy supply, which is difficult to achieve with solar and wind alone," he explains.

The initiative brings together experts in nuclear technology, safety, chemistry, materials science, and process industries, aiming for finding solutions for energy-intensive processes like hydrogen production and, critically, providing the high-temperature heat that industries require.

“Nuclear reactors generate a lot of residual heat—energy that today is often wasted by being discharged into the sea," says Christophe Duwig, Professor at the Department of Process Technology.

Currently, only 35% of the energy produced by water-cooled nuclear reactors is converted into electricity, with the rest being lost as heat. Today's water-cooled reactors cannot reach the temperatures needed by industry since the cooling water in the reactors boils at a relatively low temperature.

Future reactor technologies will use new coolants, such as gas or lead, that can be used at much higher temperatures, opening up new possibilities.

"Some of the small modular reactors (SMRs) use innovative coolants could reach temperatures as high as 1,000°C – enough to replace fossil fuels in most industrial processes," says Duwig.

SMRs are smaller reactors that can be built in modules, allowing them to be completed faster and cheaper than traditional reactors. Their flexibility and size make them particularly suitable for industrial clusters.

Safety at the core

"The key to the reactors of the future lies in material development," says Olsson. At KTH, researchers are developing advanced steels capable of handling the extreme conditions, such as corrosion, found in SMRs with lead coolants.

KTH is also engaging with industry representatives to better understand their challenges and explore opportunities for collaboration.

But nuclear technology also raises questions about safety, waste and social acceptance. Safety remains a central focus for nuclear technology, Olsson emphasizes.

"The new reactors we are working on incorporate passive safety systems, meaning they can cool themselves without manual intervention during an accident," says Olsson.

Another significant advantage of advanced reactors is their potential to recycle nuclear fuel. Gas- and metal-cooled reactors can be designed to reuse nuclear fuel, optimizing uranium usage and addressing a large part of the waste challenge. Still, public acceptance of nuclear energy is critical.

"I believe people will become more open to fourth-generation reactors as they learn about their safety and efficiency. But we need to keep working on transparency," says Olsson.

Together with Duwig, he hopes the KTH initiative will play a vital role in Europe’s energy transition.

"Creating a strong, fossil-free industry in Sweden and Europe is a complex challenge that requires collaboration and shared efforts," says Duwig.

Text: Anna Gullers