KTH Energy Platform visits the lab where sustainable materials are being designed for the future

KTH Energy Platform’s visit to the Department of Materials Science and Engineering included a well-received tour of labs and research centres. This is where new materials, methods and products are created with properties that are tailored for a more sustainable future.

The KTH Energy Platform was represented by Director Lina Bertling Tjernberg, Deputy Director Christophe Duwig; members of the Platform’s reference group, Björn Laumert and Pernilla Hagbert; and Pierre Bodin, Research Advisor for Strategic Initiatives. Together, they gave an overview of the Platform’s work on creating a foundation for closer co-operation between KTH energy researchers.

Annika Borgenstam, Head of Department at the Department of Materials Science, started the day’s presentations. She spoke about how researchers at the department focus on metallic and ceramic materials, covering everything from processes to structures and properties - the three areas into which the department is organised.

The department is also home to the Hultgren Laboratory, which is an open KTH lab for materials science researchers. The Hultgren Laboratory plays a key role in experimental research into materials development with material characterization; the facility also works closely with industry. A so-called Atom probe tomography instrument is currently being installed here, which will offer a rare and powerful materials analysis technique.

The Hillert Modeling Laboratory has also opened recently, which provides improved opportunities to share computer-based modeling tools and expertise within the department. This modeling is set to improve materials-related research and development by predicting outcomes and reducing the number of unsuccessful attempts. Hero-m 2i, the Center for Mechanics and Materials Design (MMD), and the Center for Synchrotron Light in Materials Science (CeXS) are also based at the Materials Science and Engineering Department.

“We have a very strong collaboration with industry; we have worked with Sandvik for many years, and we’re now launching a partnership with SSAB. We also have researchers who are involved in the development of carbon dioxide-free steel production under the auspices of Hybrit,” says Borgenstam.

Flexible methods for solar cell manufacturing

Liubov Belova then spoke about her research which has resulted in a new manufacturing method for solar cells made from perovskite. Using a technique similar to that of a standard inkjet printer, perovskite solar cells can be printed in different shapes and on different materials.

This manufacturing method has sufficient capacity to meet today’s industrial requirements and can reduce material use. The method has been designed to be as simple and accessible as possible. Solar cells can be made thin and light, and can be printed on flexible surfaces and in shapes that allow them to be fitted to existing products or applications. In addition, the technology can be used in the field, for example in disaster environments, with electricity production being controlled remotely.

One of the challenges associated with the technology is that perovskite does not yet have as long a lifetime as other solar cell materials. However, this is countered by the low cost of manufacturing.

Liubov Belova also gave details of a project to develop photocatalytic production of hydrogen using ultraporous active films based on oxides without the use of platinum or other rare and hard to source materials. This method is extremely efficient, making it competitive. It can also be integrated with other functions such as purifying water.

Non-toxic button batteries

Next up was Veena Singh who talked about research that has resulted in a new form of rechargeable button battery which replaces lithium with non-toxic materials. Researchers have developed electrodes covered with activated biochar and saltwater solutions such as electrolyte. The result is a supercapacitor that can replace today’s button batteries. The research has been supported by the IRIS interdisciplinary project which is run at the ITM school.

Claudio Patricio then spoke about research into new tools and methods that, among other things, model new materials for hydrogen storage. Computer modeling makes it possible to carry out research where experiments or trials are too difficult or time-consuming. Modeling is an effective way of selecting different approaches in the development of new materials.

Additive manufacturing reduces materials use

The last of the project presentations was given by Ethan Sullivan who provided insights into new methods in additive manufacturing. He showed examples of a new form of copper heat exchanger manufactured at the department. The heat exchanger creates an energy loop between electricity and waste heat which could cut operating costs in energy-intensive industries.

Additive manufacturing is more sustainable as it requires smaller amounts of materials and consumes less energy. The research is strongly interdisciplinary as it requires knowledge in all steps from design to production and optimization of materials and manufacturing methods. This research is also supported by the IRIS project at ITM.

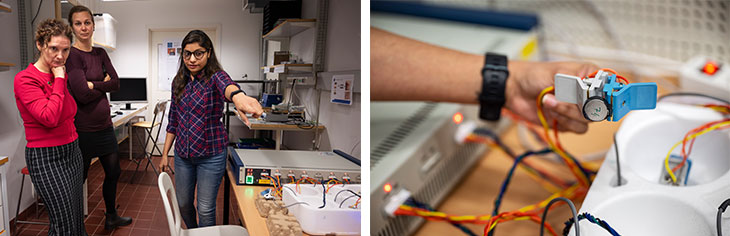

The visit ended with a tour of labs and facilities, including a visit to the Hultgren Laboratory.

Text: Magnus Trogen Pahlén