Project to boost machinery components' life

A new project aims to improve the lifetime of machine parts by utilizing advanced surface functionalization of components. Researcher Robert Tomkowski from the Department of Production Engineering is in charge of this effort.

Modern machinery requires continuous efficiency improvement, especially in the shift towards multiple life cycles of the components. A key factor in enhancing their lifespan involves optimizing the surface characteristics.

“Surface functionalization is a natural step in the evolution of existing processes towards circular manufacturing,” says Robert Tomkowski, a researcher at the Department of Production Engineering.

Surfaces serve various purposes and can be broadly categorized into three groups: functional, non-functional, and decorative.

“In our research, we concentrate on surfaces with specific functions, such as cavitation resistance, wear resistance, adhesion, reduced friction, etc. The challenge here is to link surface texture and its pattern to its desired function, on the level where components’ performance can be designed and well controlled,” explains Robert Tomkowski.

Extends life cycle

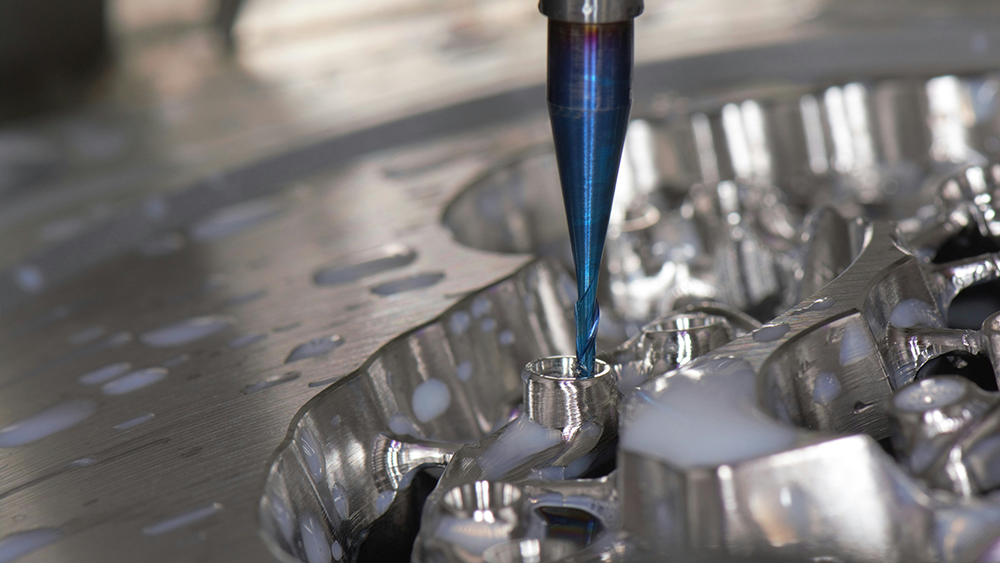

Surface modification methods, such as texturing or coating, are employed to create a designed, modeled, and simulated surface texture on components. This enhances their performance and extends their life cycle.

The surface functionalization approach is expected to prolong the lifetime of the components by at least 30%, while increasing the wear resistance of thrust surfaces by at least 50%, increasing the surface cavitation resistance by 50-70%, hence reducing the premature failure of the machinery by at least 25%.

The primary challenge, according to Robert, is to achieve advanced surface modification in a reliable and repeatable manner. Therefore, measurement methods and the characteristics of the modified surface are equally important and are part of this research.

The project also seeks answers to questions like designing circular products (surfaces), assessing the feasibility of reusing/remanufacturing conventional and modified surfaces, and understanding the impact of surface texture modification on cavitation, friction, wear resistance, and heat transfer.

There is also a question about the environmental impact of currently used technologies and those used for surface functionalization.

“For that, we will develop a set of circularity metrics, informing about the status of the component in all circular stages. These metrics aim to be generalised to a full methodology of circularity assessment methodology where the environmental and economic impact of introduced technology is measurable and controllable.”

The project requires a lot of testing and measurements of surface texture and its proper linking to the planned function. Robert Tomkowski concludes:

“It will be a very interesting and work-intensive project, but all partners are determined to succeed in achieving the goals we set.”

About the project Fun4MEL

In the project Fun4MEL (Advanced Surface Functionalization for Machinery Enhanced Lifetime), the researchers will define what is required to enhance the lifetime of machine parts through advanced component surface functionalization, suitable also for reuse or remanufacturing. The project is a collaboration with Scania CV AB, Siemens Energy AB, Duroc Laser Coating AB, VibiCore AB, Laser Nova AB, Tribonex AB, and SWERIM AB.

Fun4MEL is founded by Vinnvova in the latest Circularity call . The project started in November 2023 and will end in December 2026.